Vertical Shiplap

A contemporary, refined vertical exterior finish. Vertical Shiplap Weatherboard Cladding has clean vertical lines that provide a sleek, smart, and contemporary appearance. This system provides a smooth, linear path that can bring the impression of height and add a strikingly distinctive look to the building.

Available Species

Scope of Use

JSC VertiClad Vertical Shiplap Weatherboard Cladding System installation is to be completed as per JSC VertiClad technical literature, within the scope of JSC VertiClad CodeMark Certificate CMNZ30084.

JSC VertiClad: Vertical Shiplap Weatherboard Cladding System

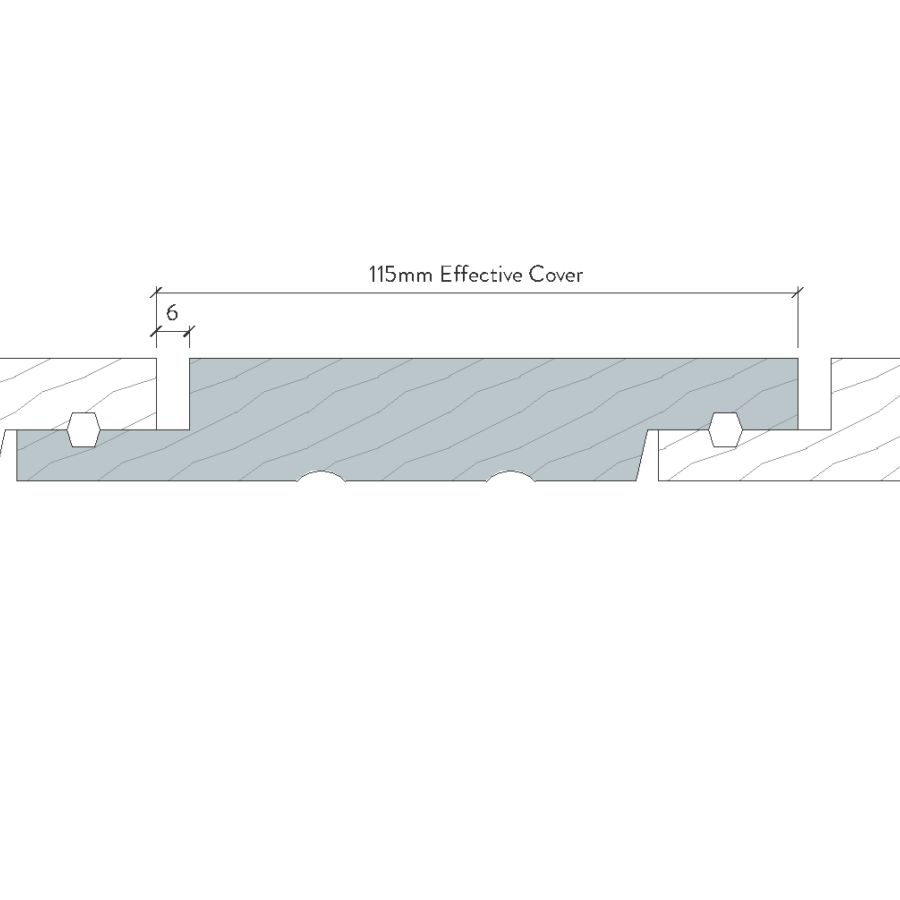

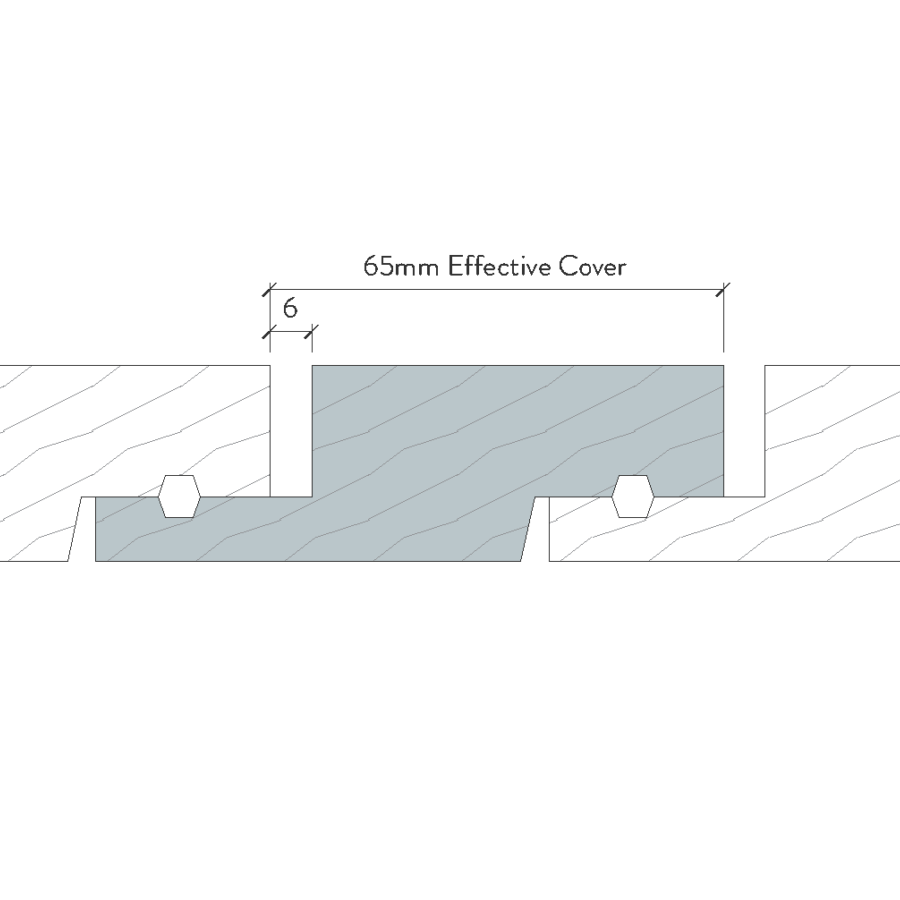

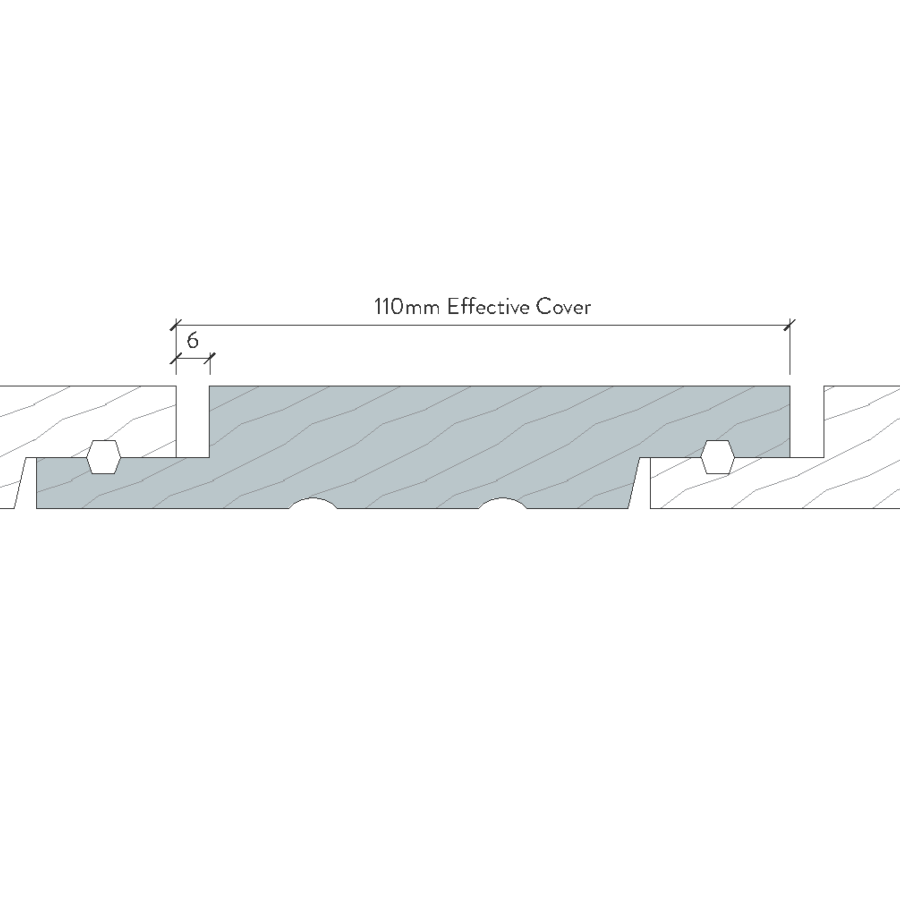

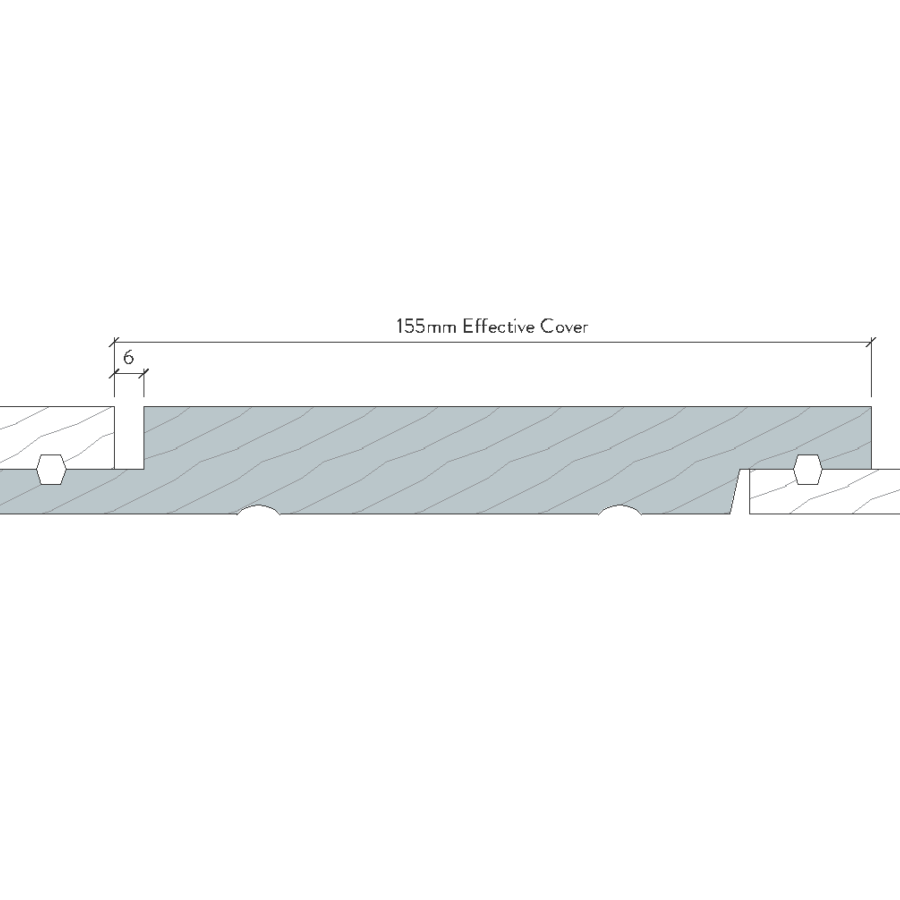

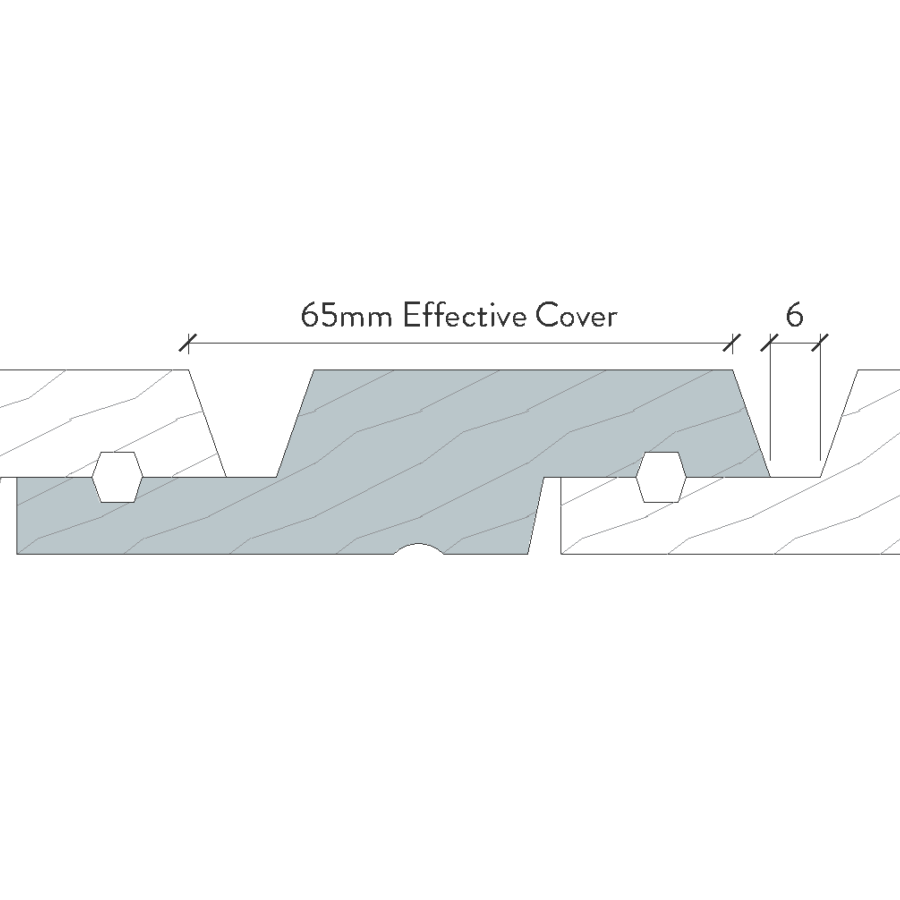

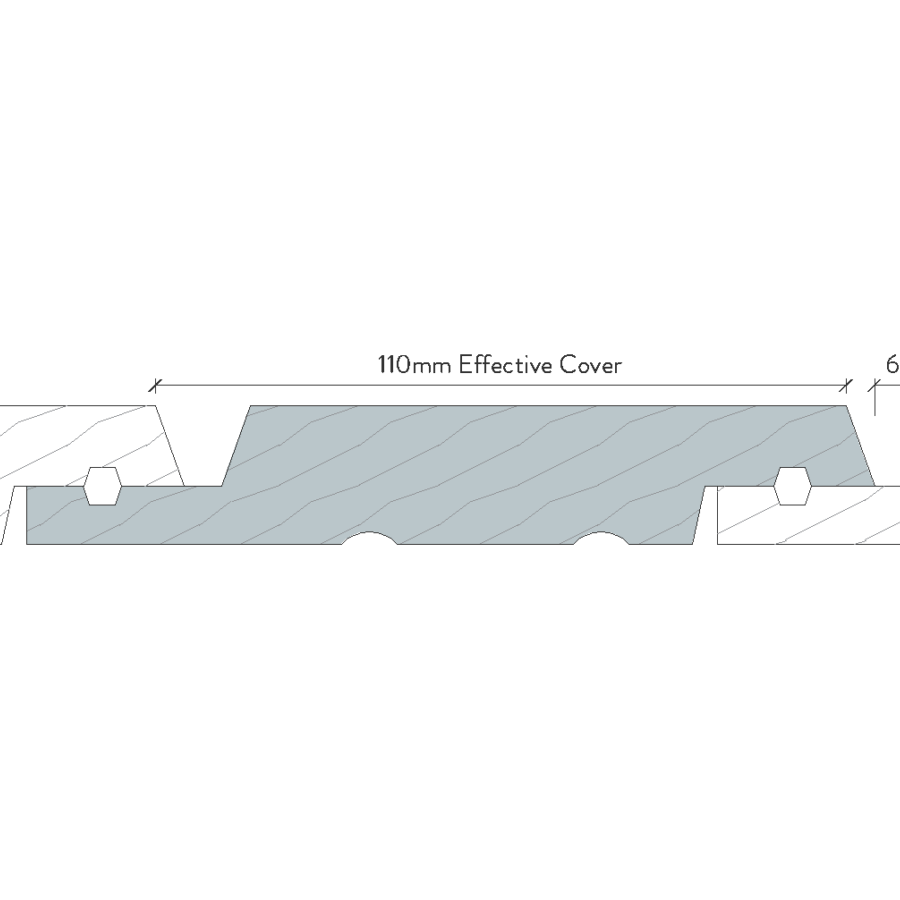

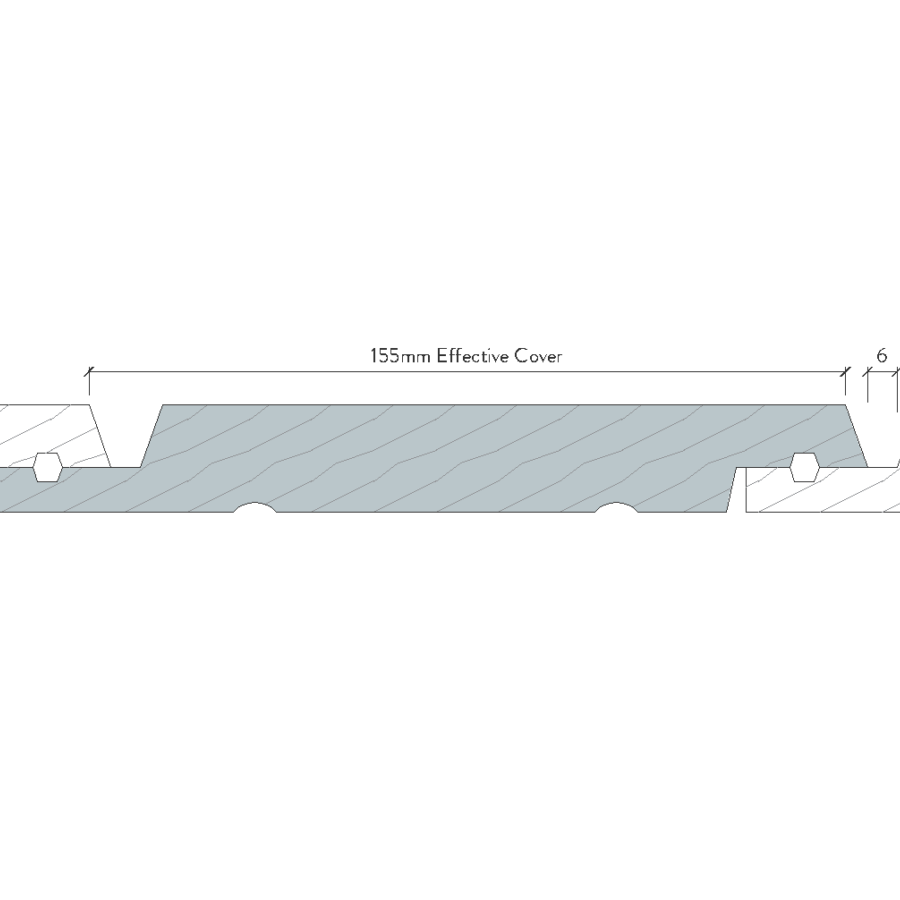

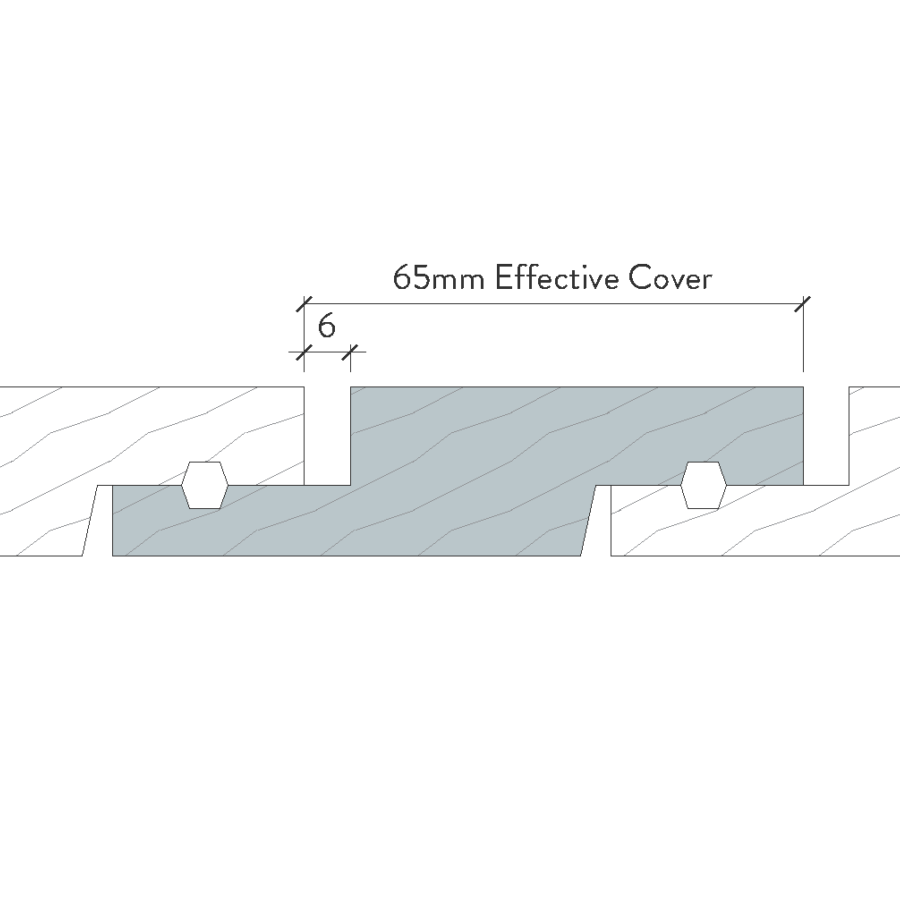

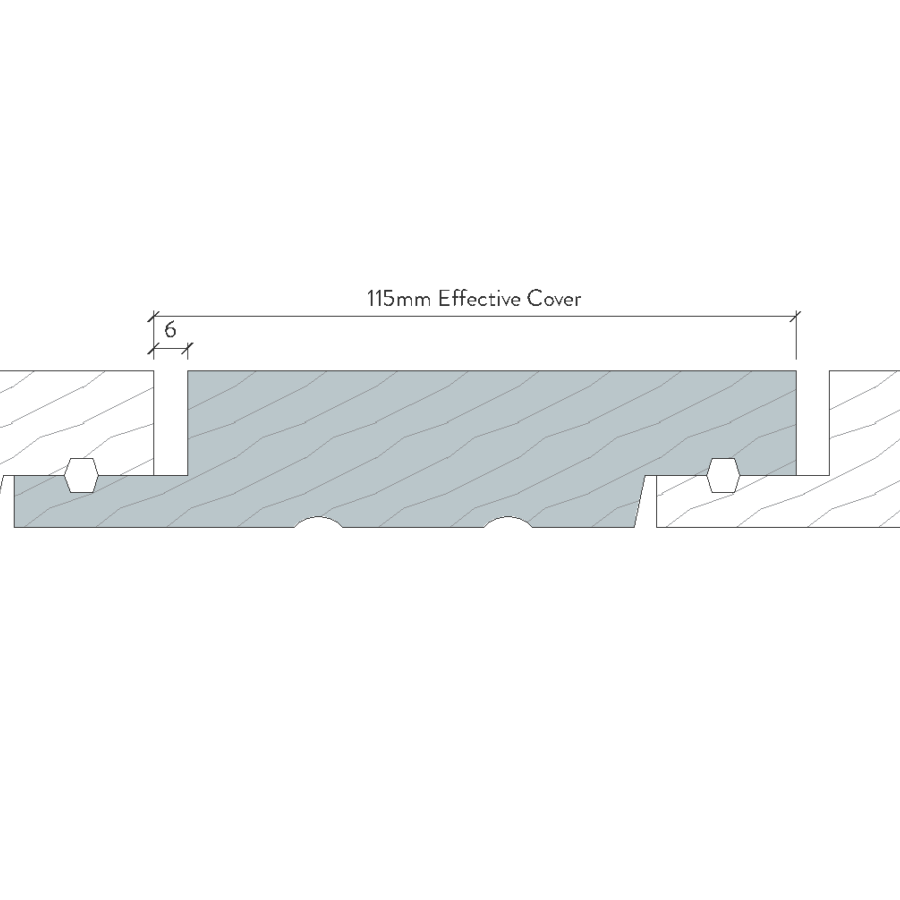

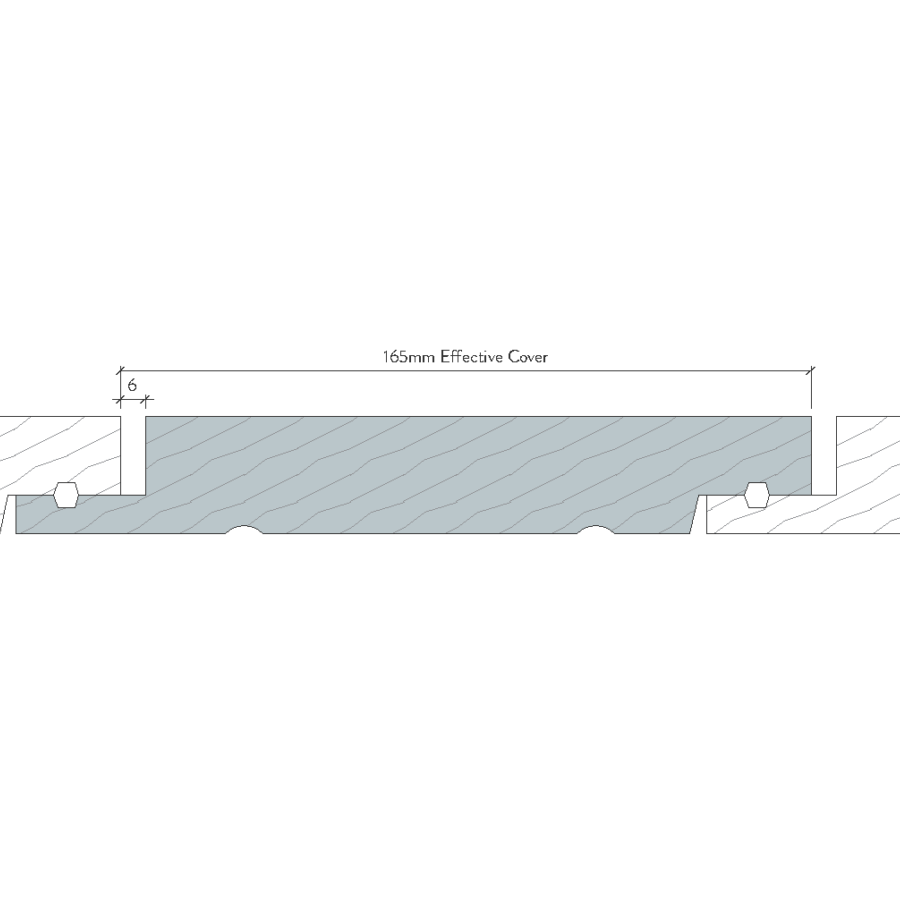

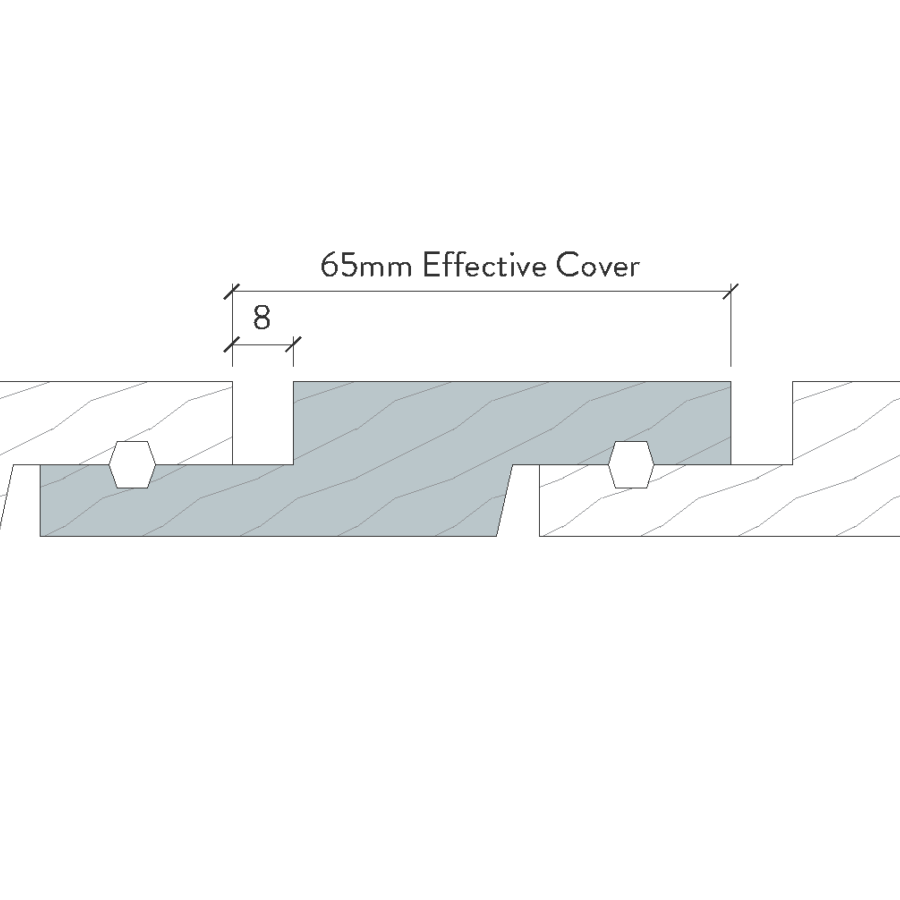

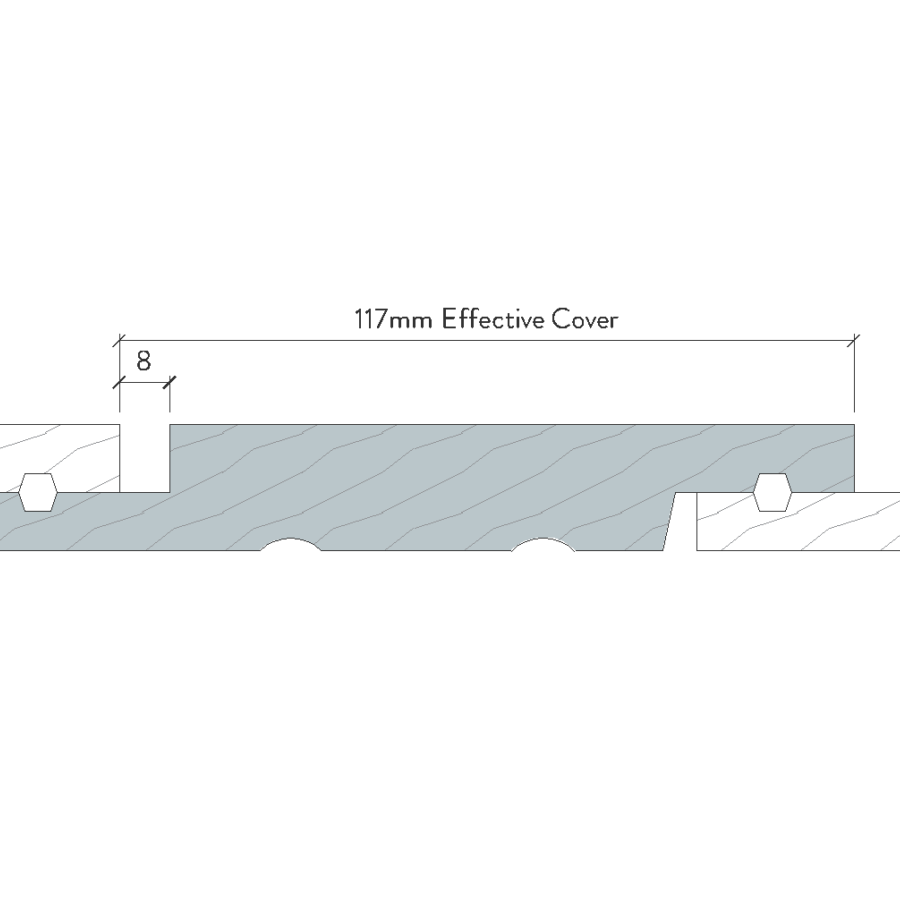

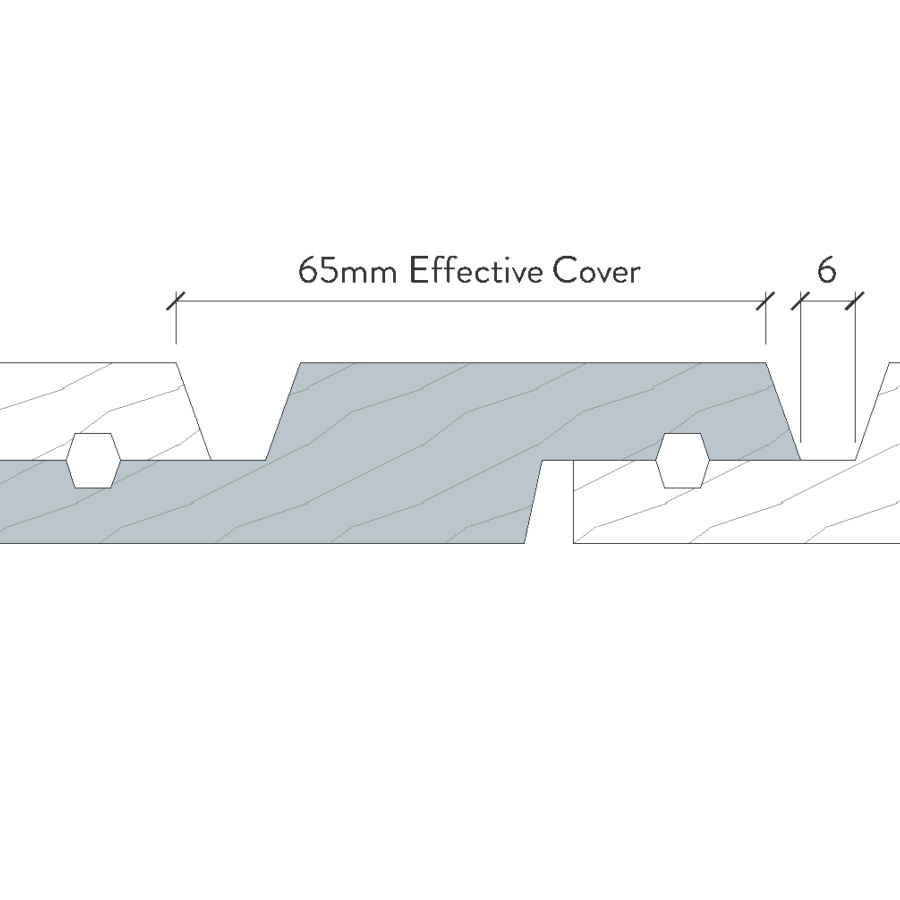

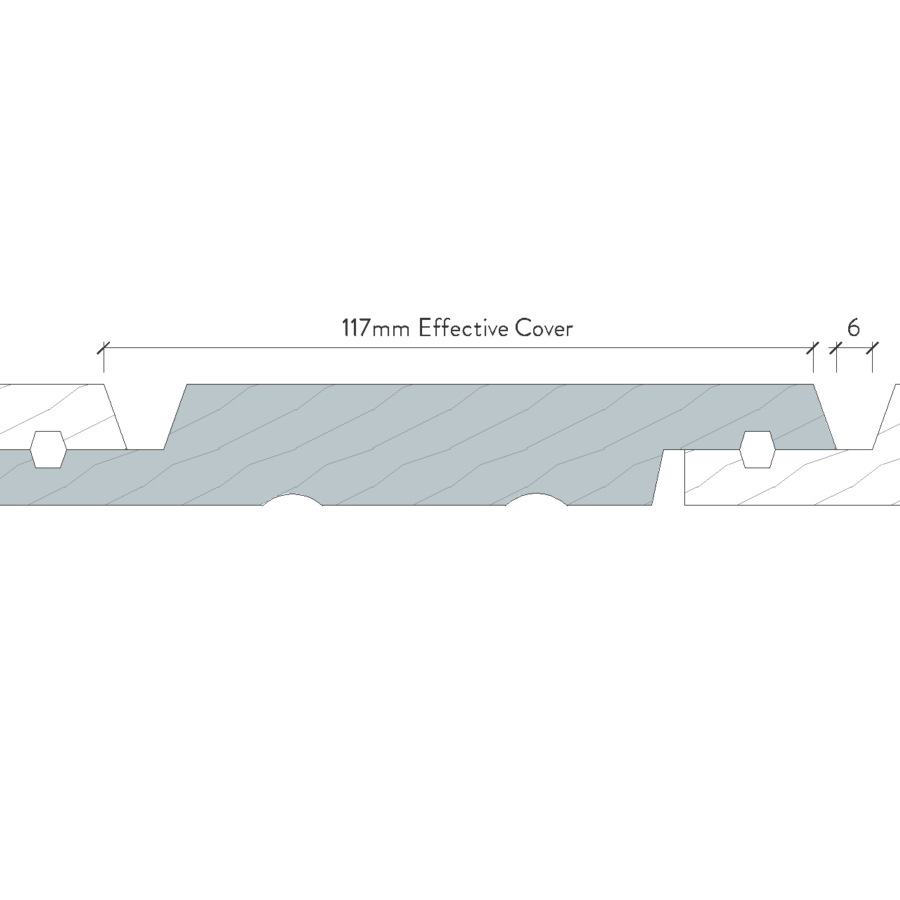

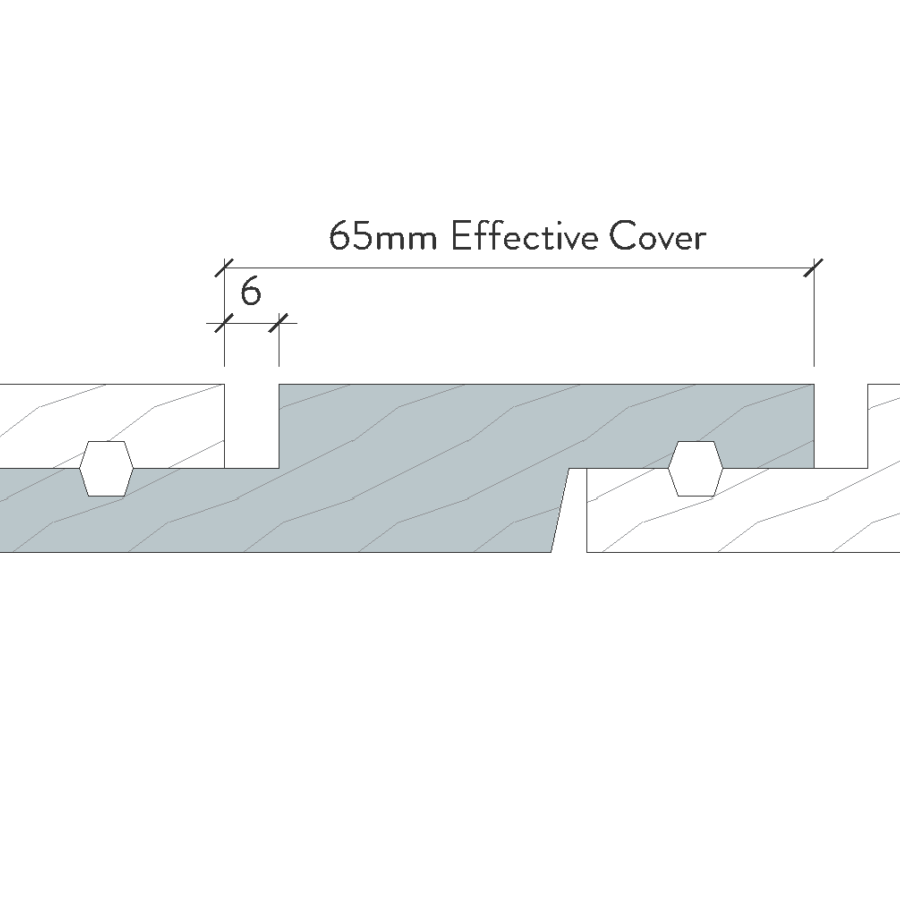

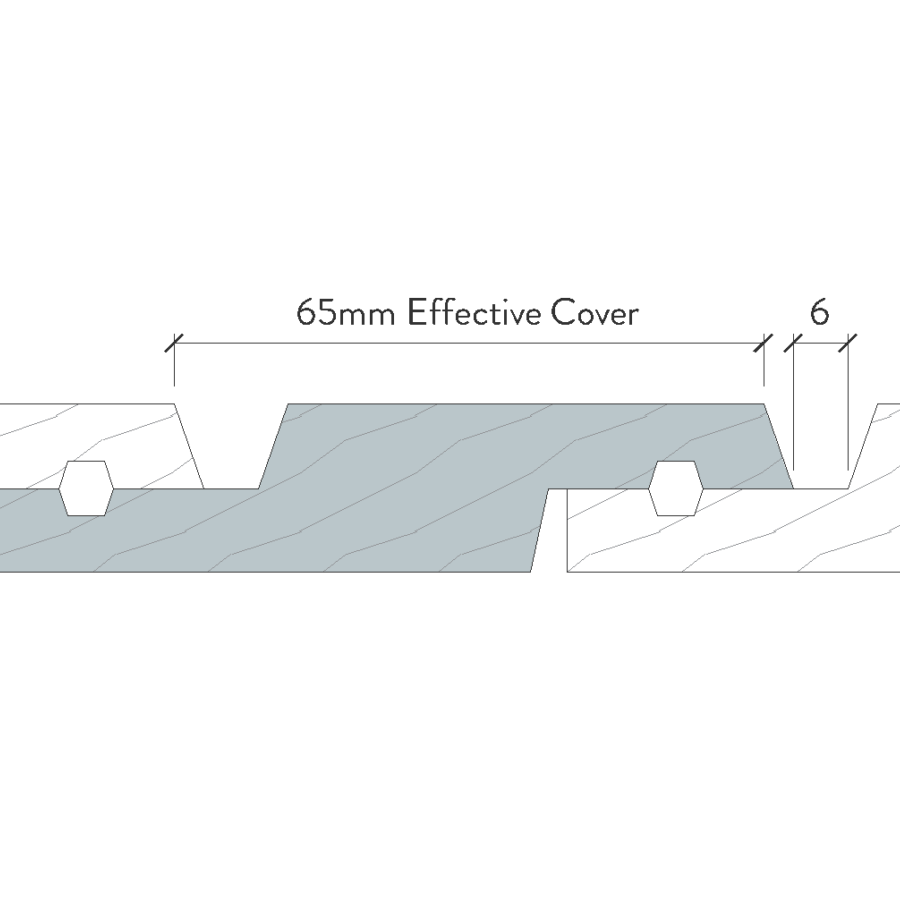

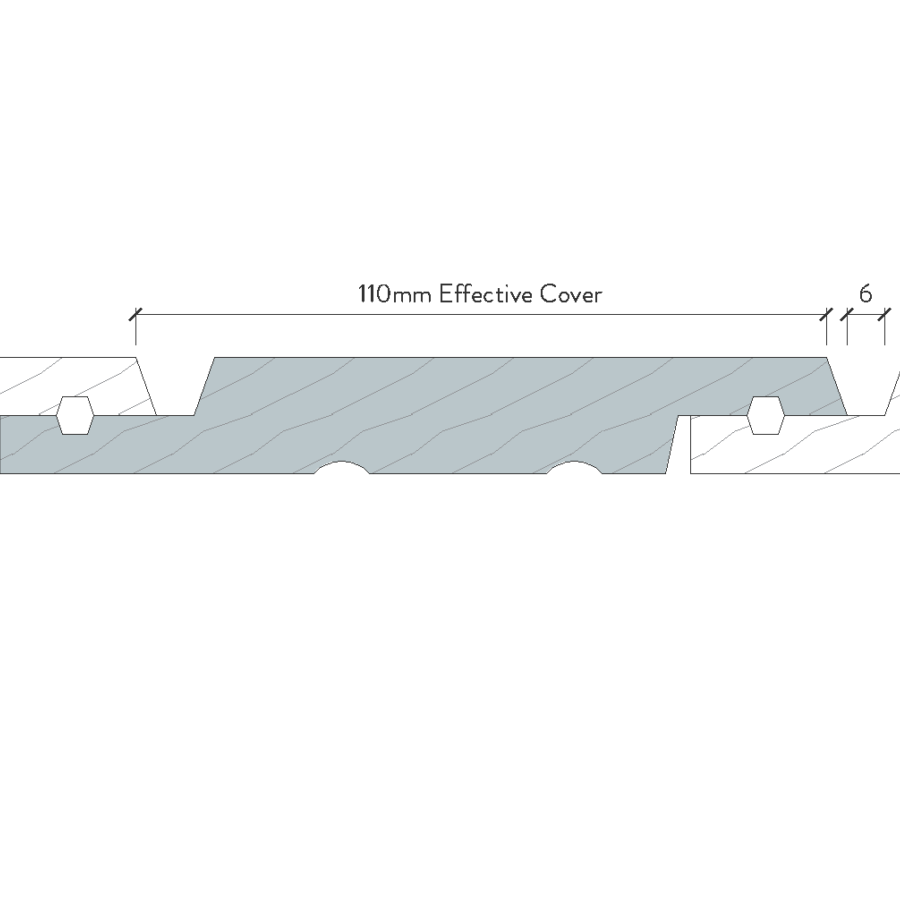

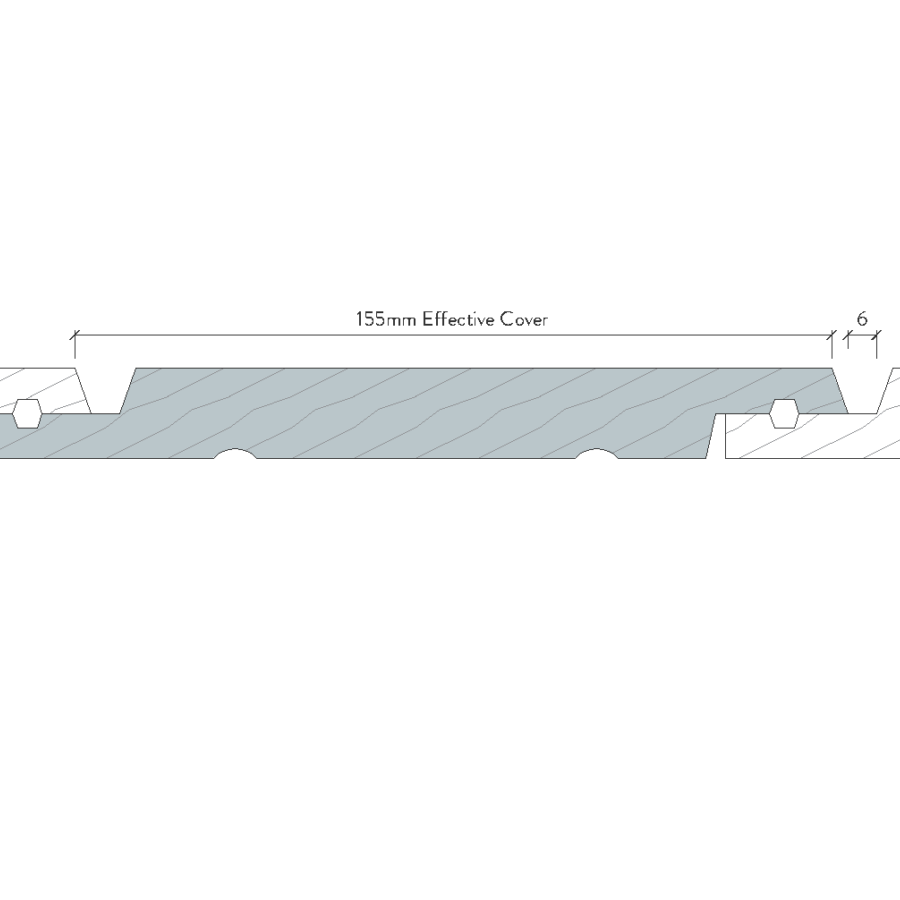

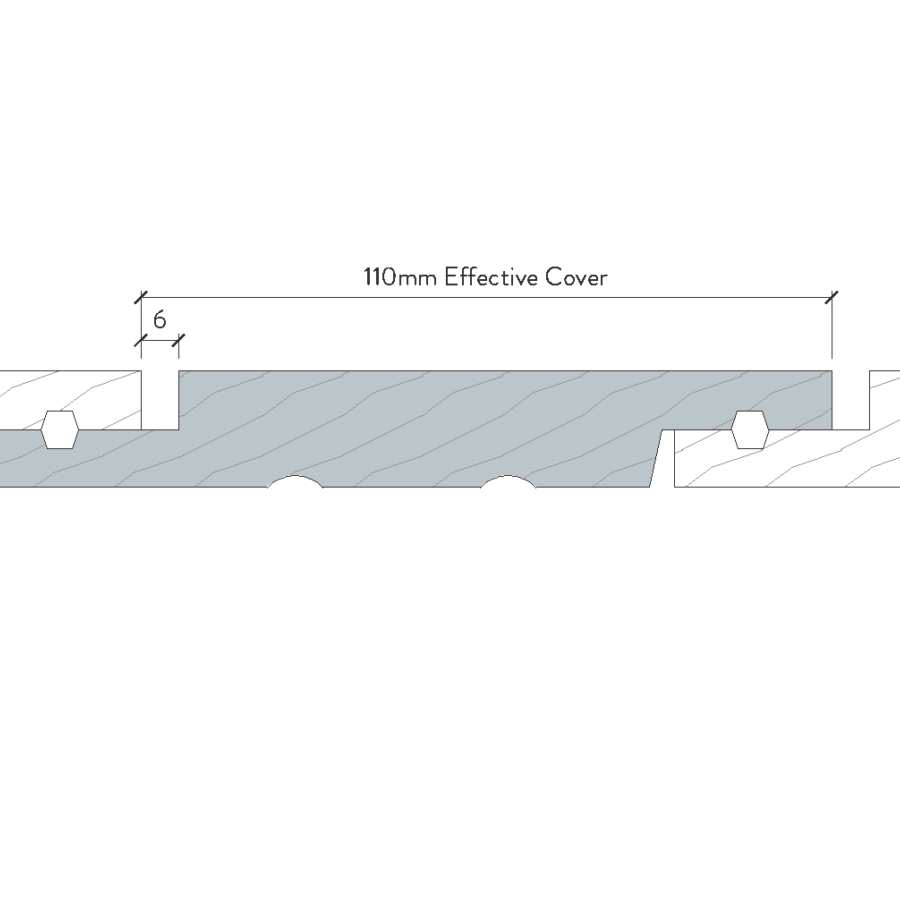

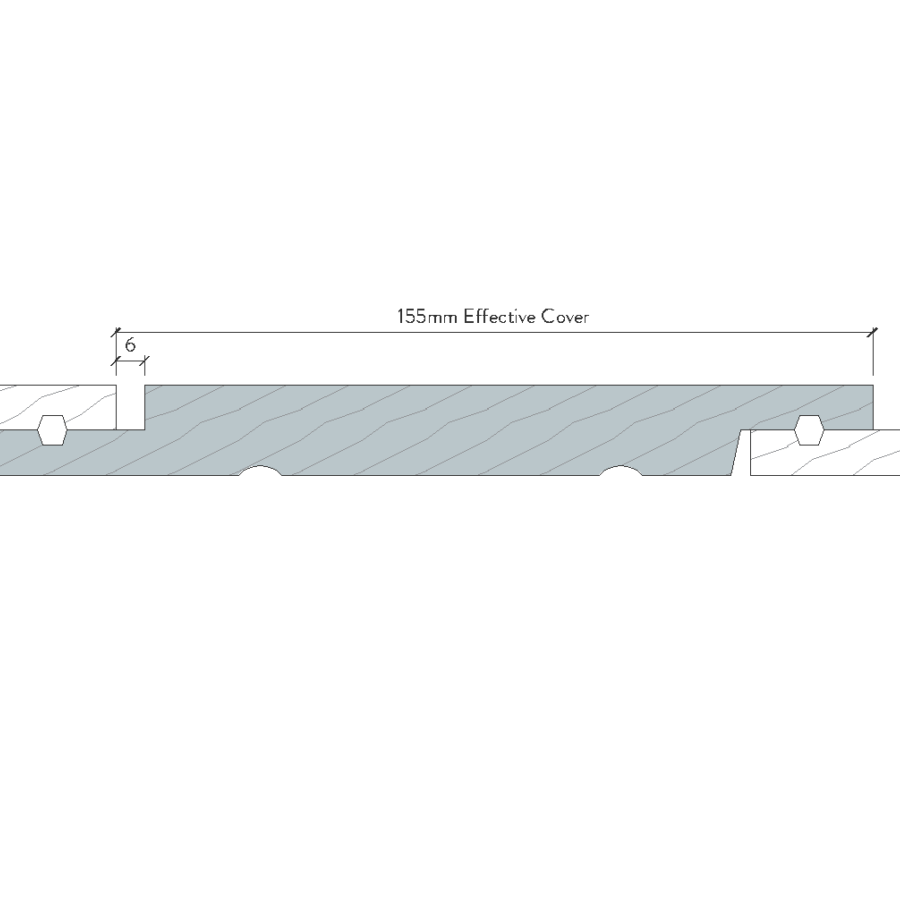

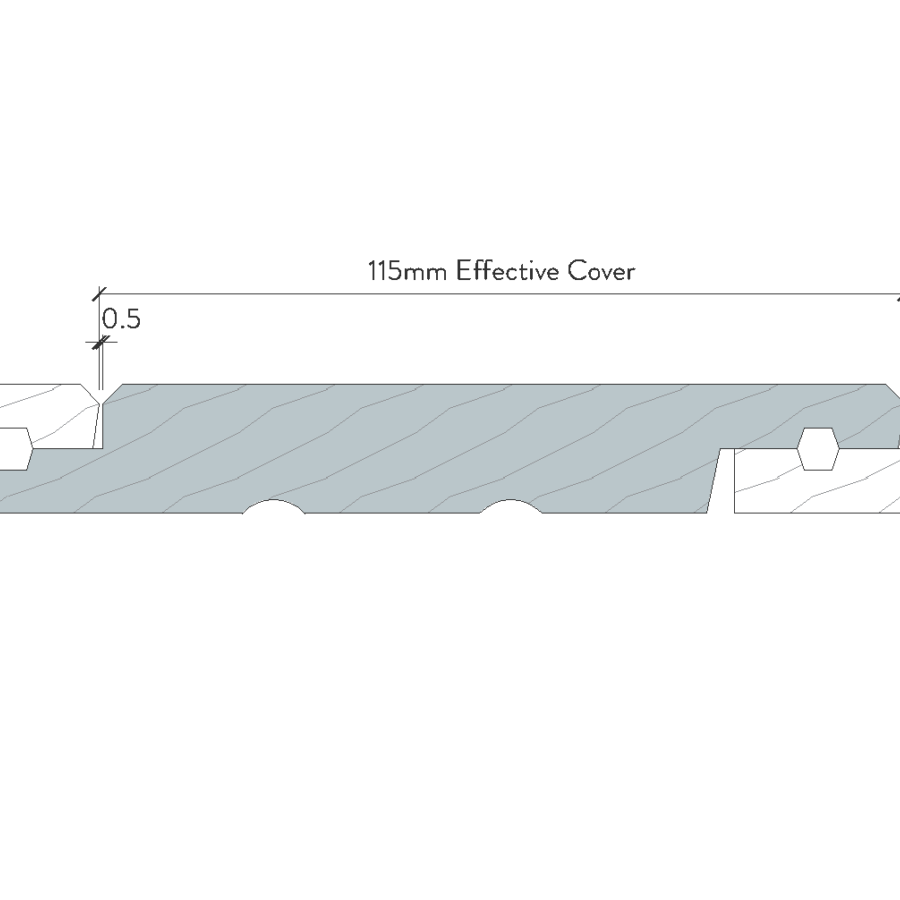

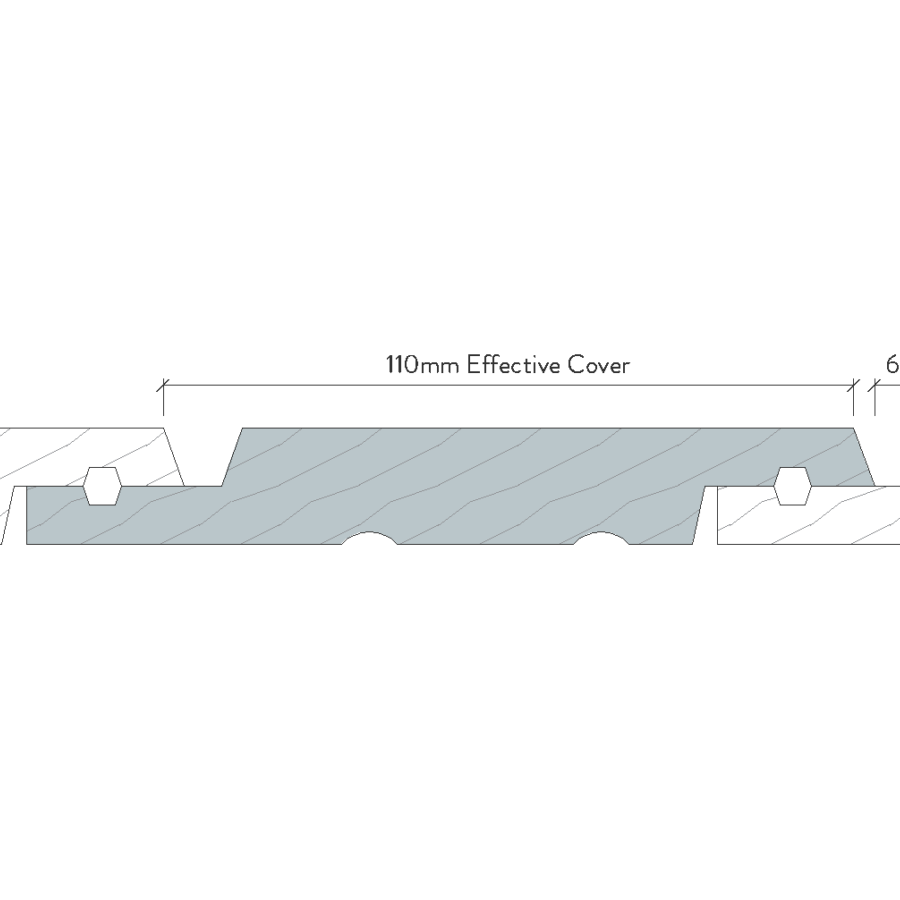

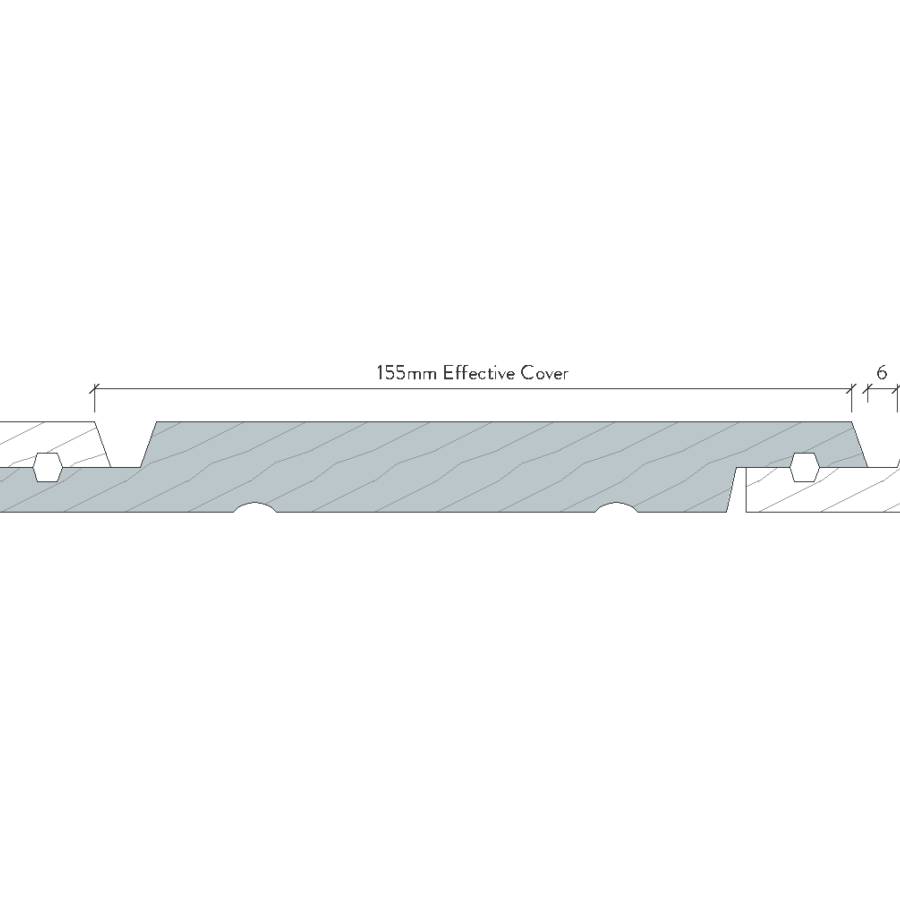

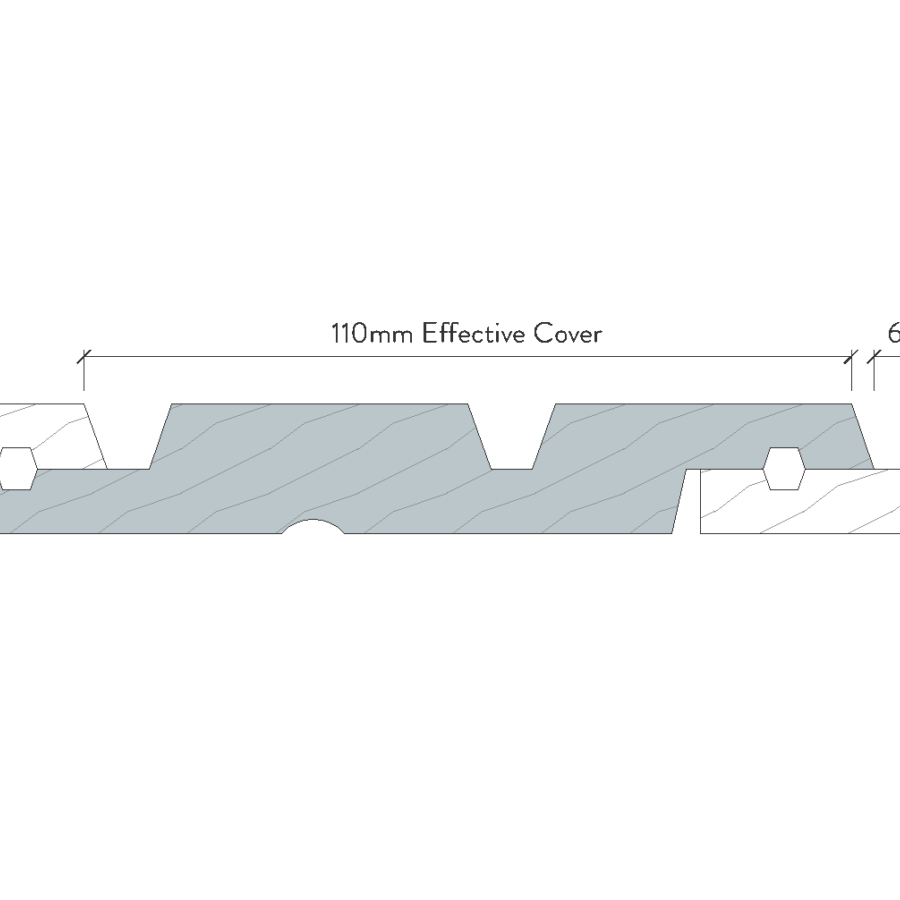

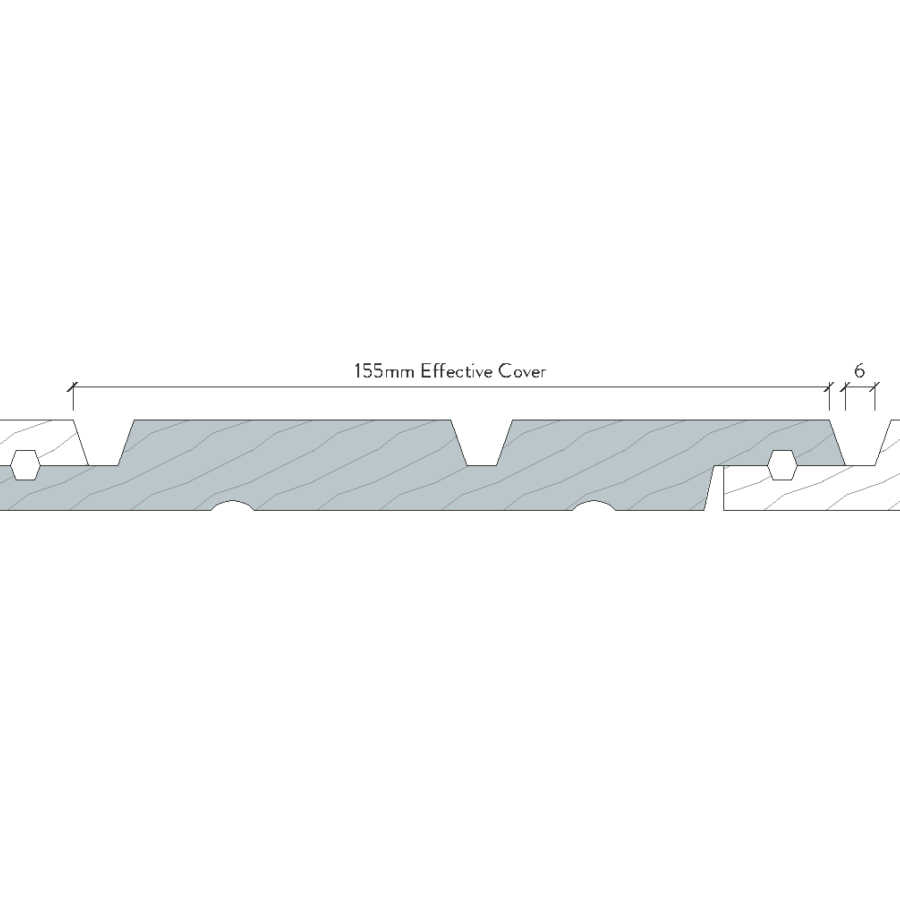

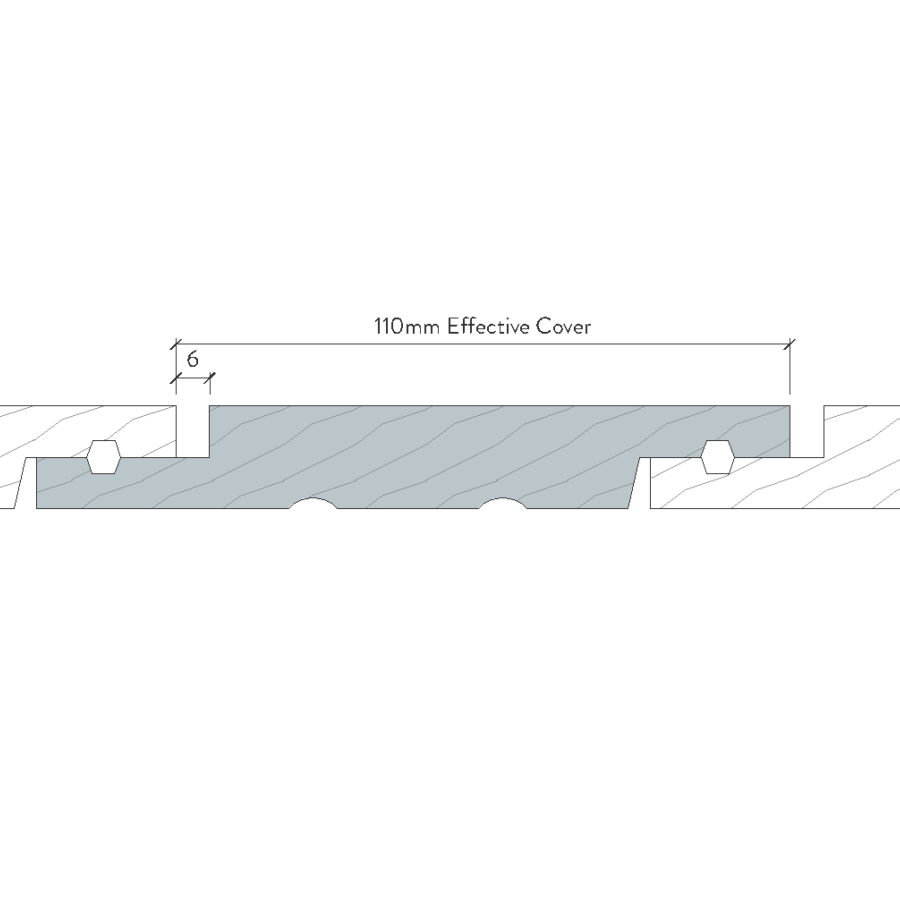

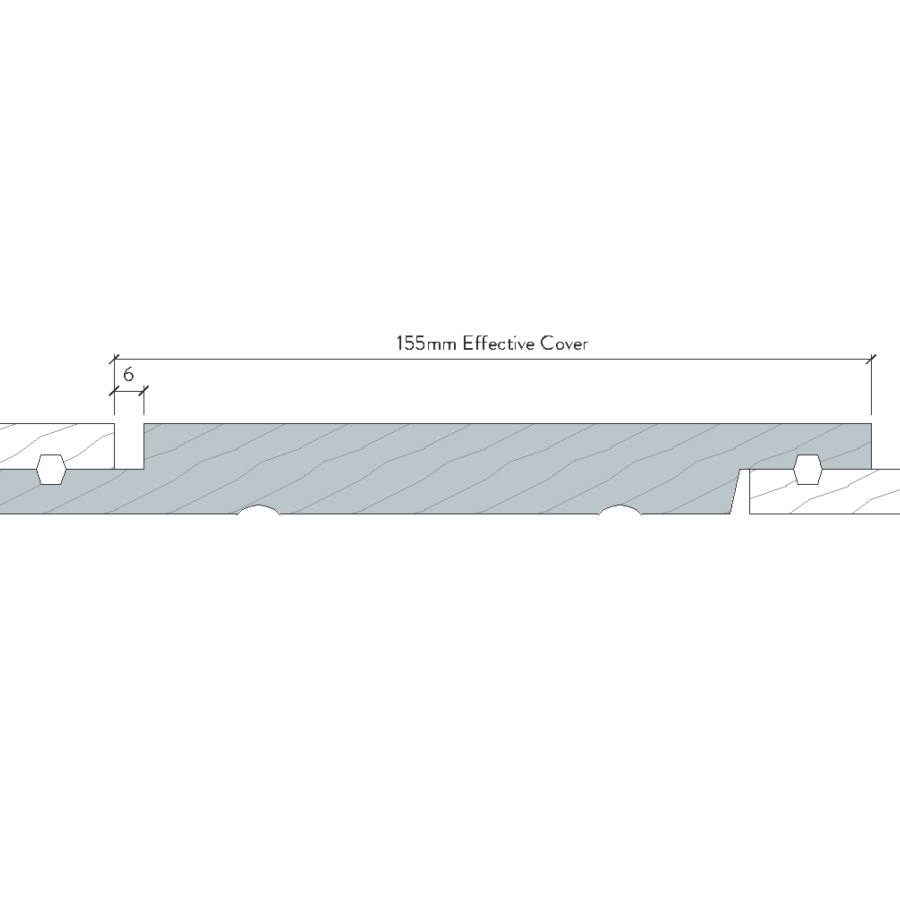

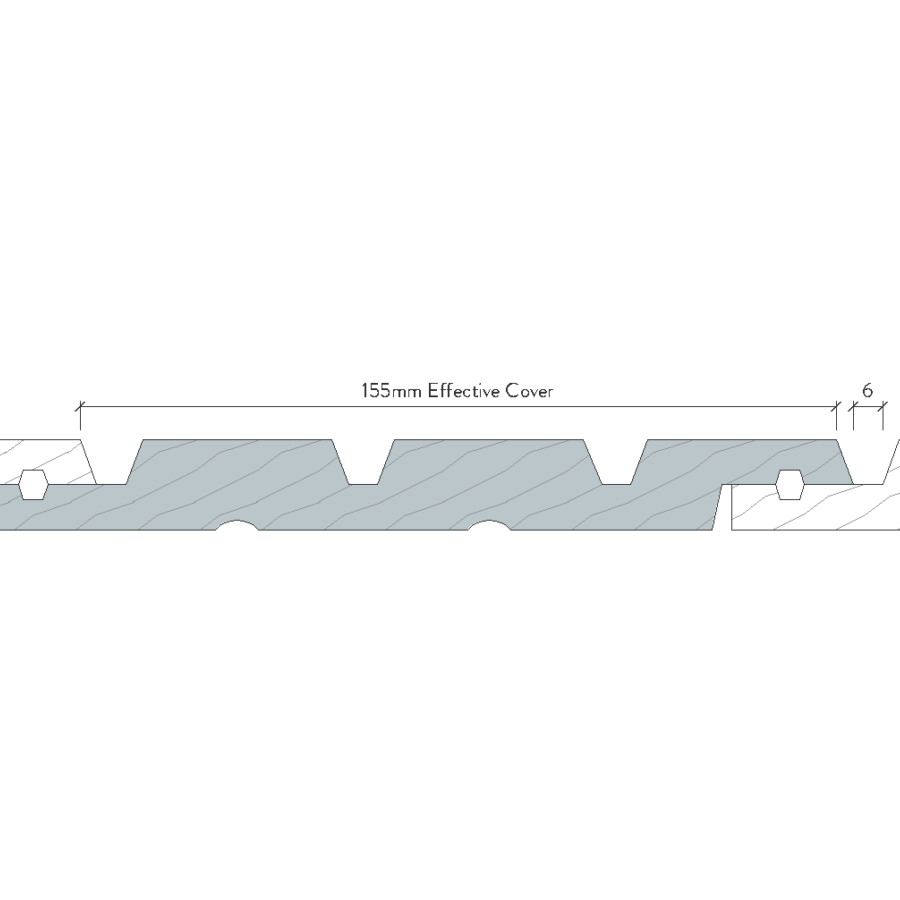

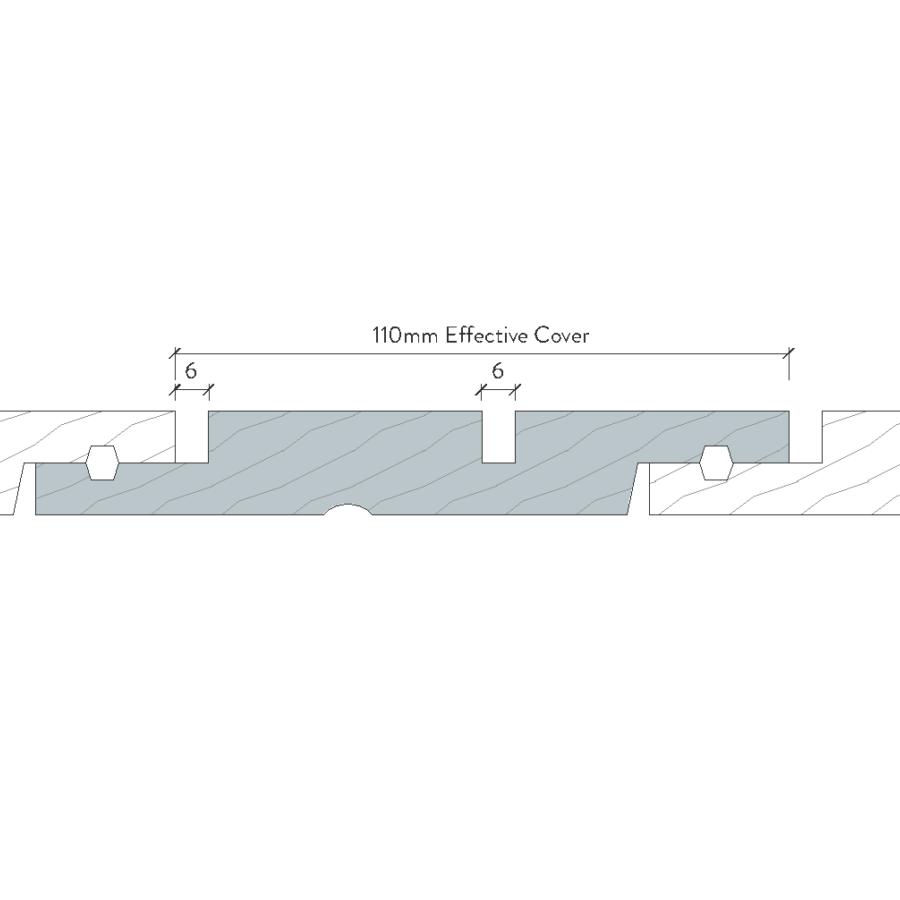

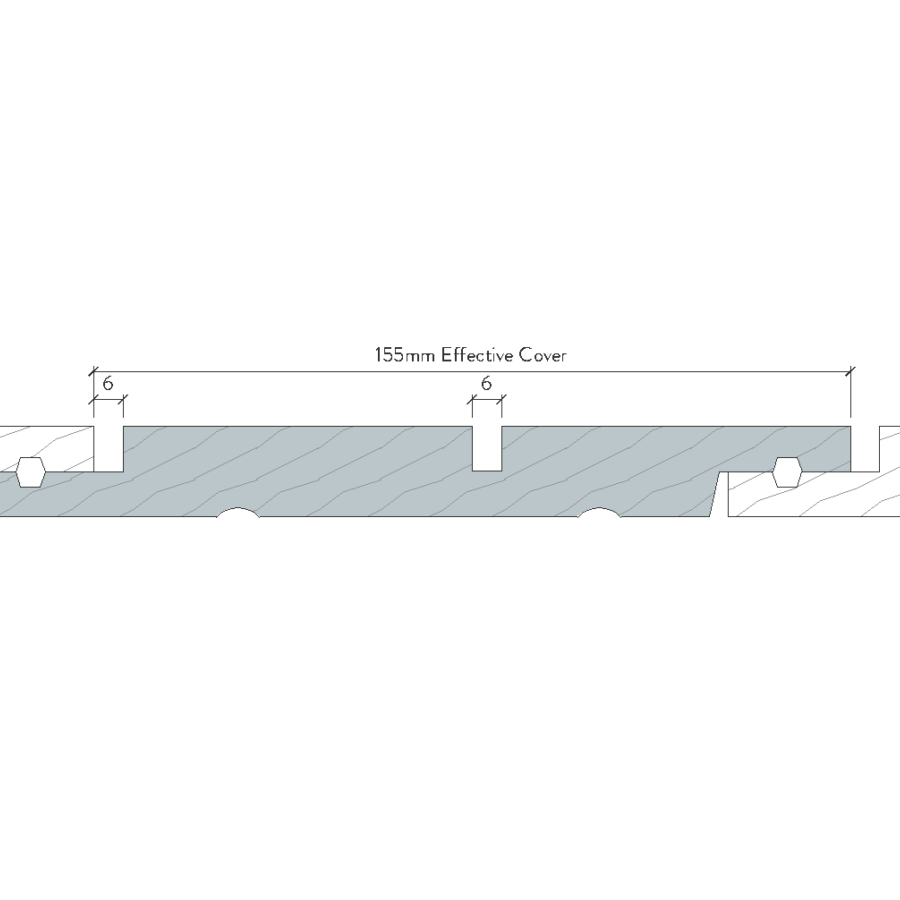

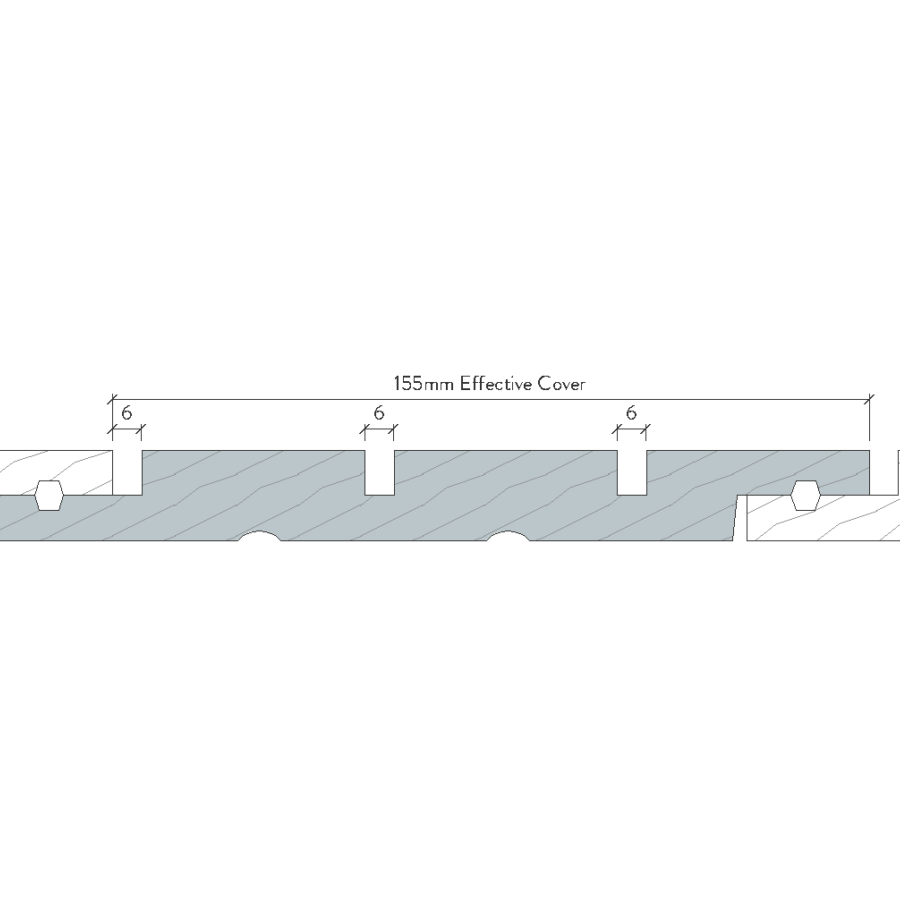

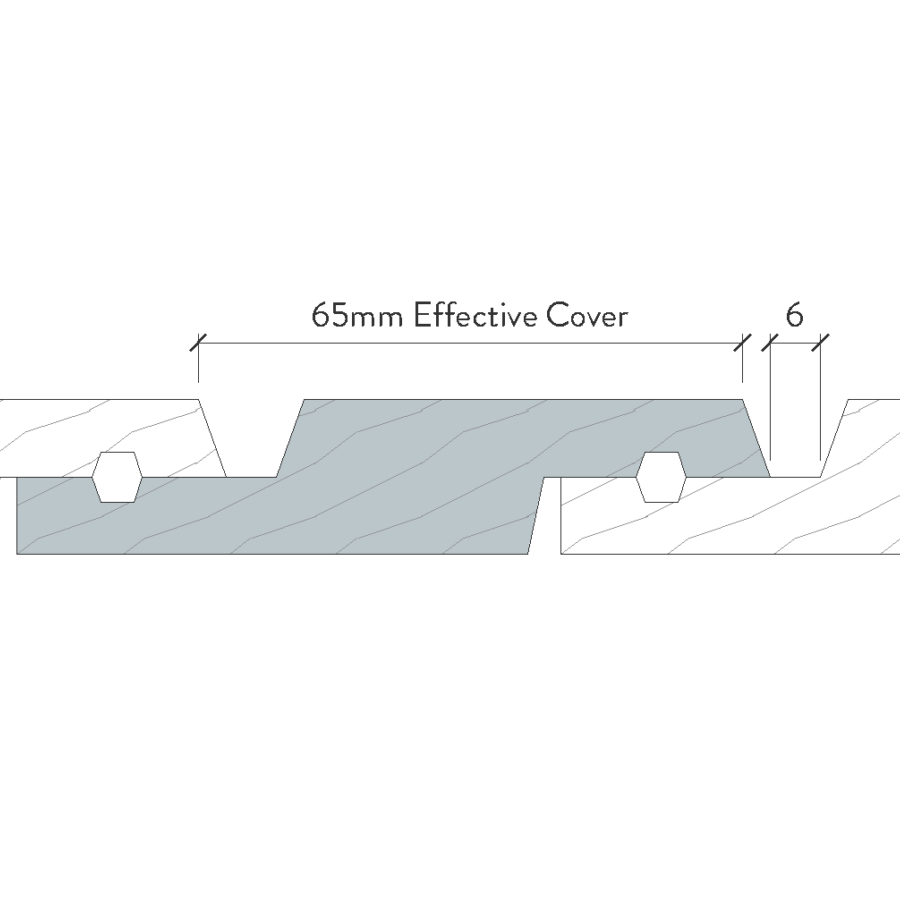

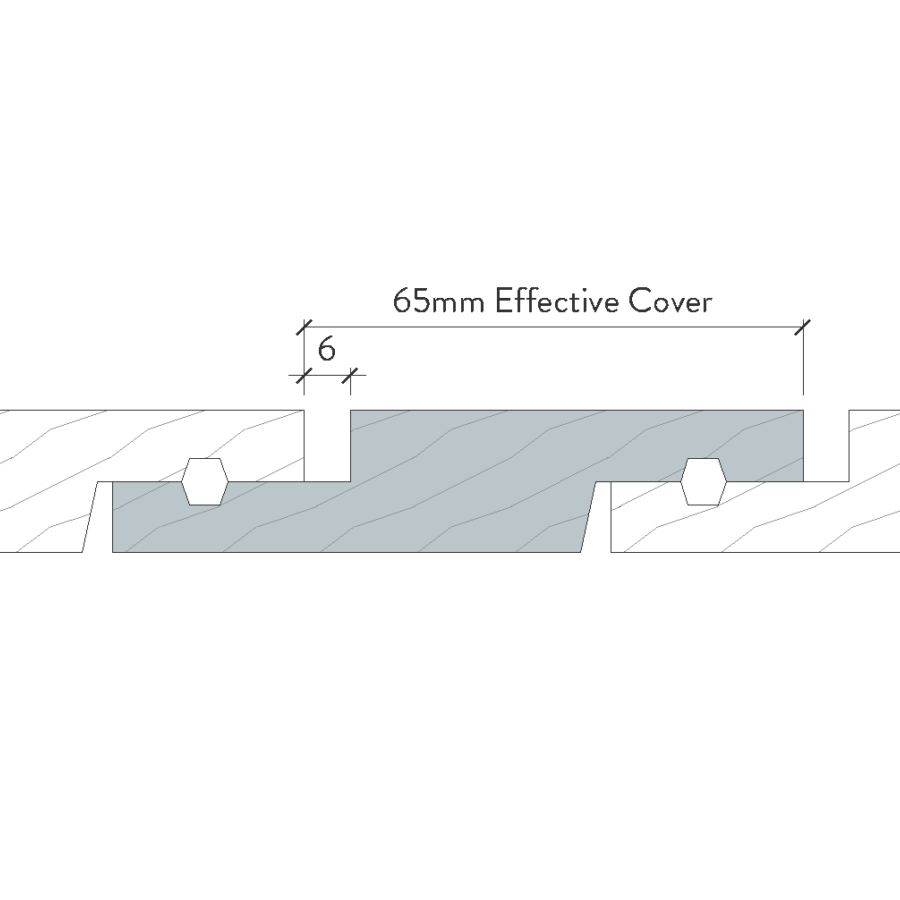

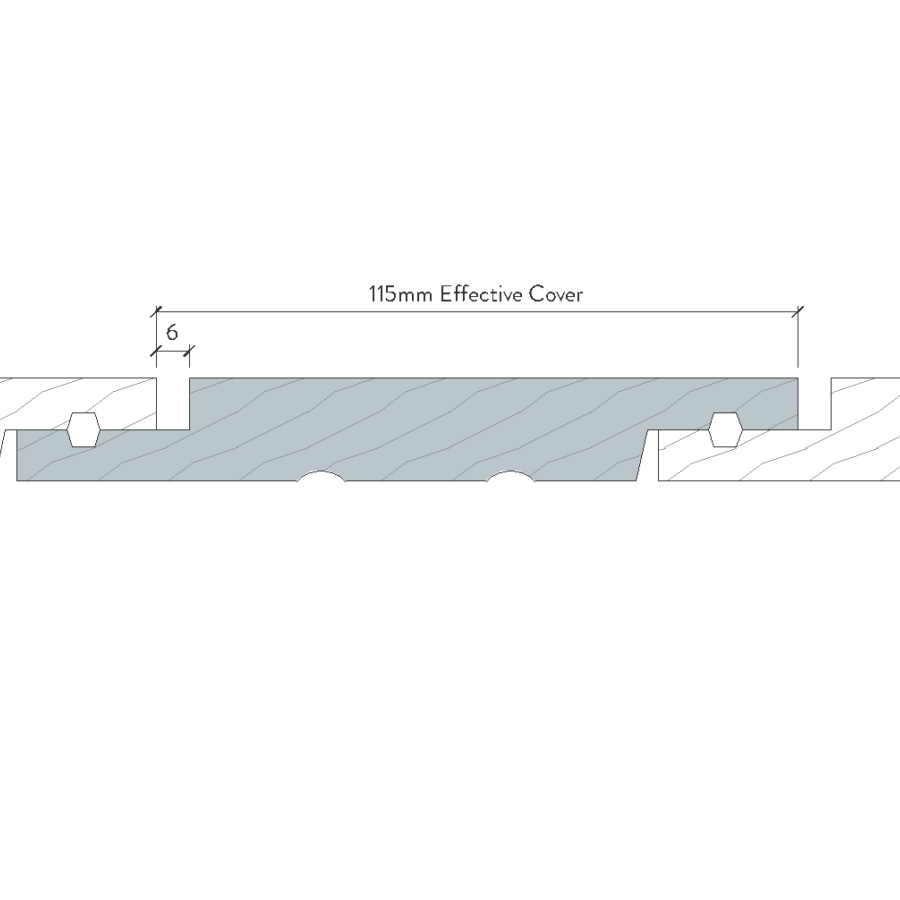

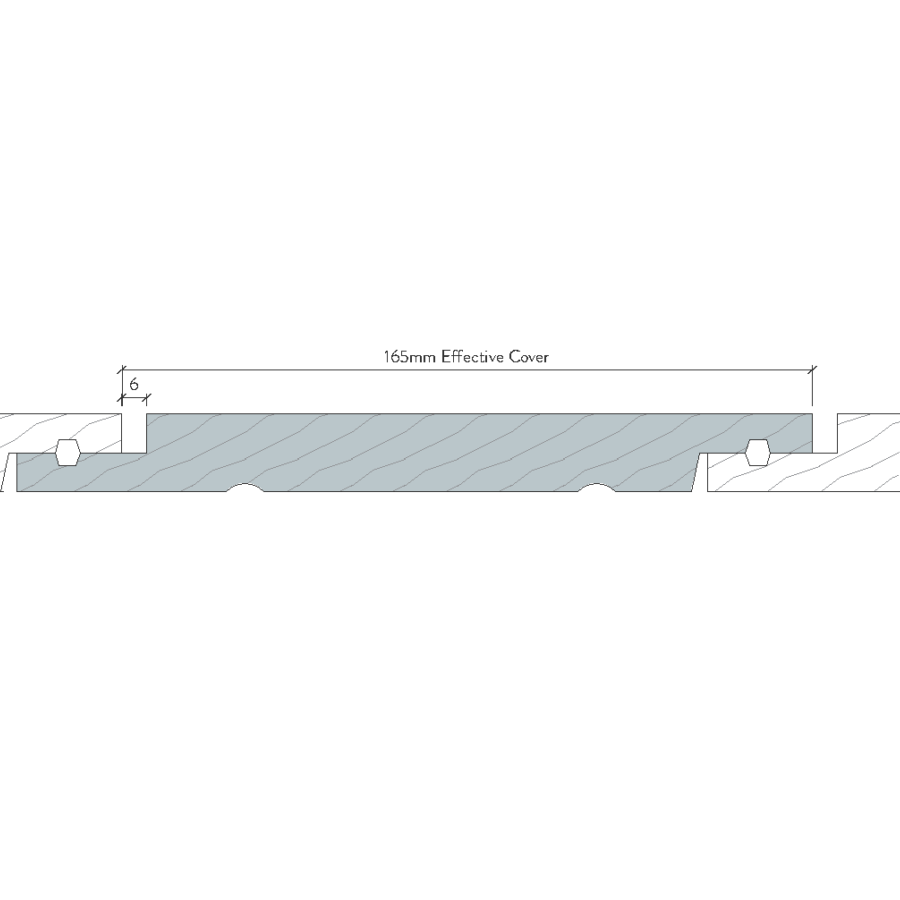

JSC proudly pioneered New Zealand's first fully tested vertical-cavity system for Western Red Cedar. VertiClad is a cavity-based system that uses vertical shiplap weatherboards to create a sleek and modern look. The vertical shiplap weatherboards fit into the JSC VertiClad Cladding System, which is a collection of different vertical shiplap profile types.

This cavity-based exterior wall cladding system comprises of:

- Vertically fixed JSC Vertical Shiplap Weatherboards

- H3.2 treated timber castellated structural or non-structural cavity battens

- Fixings

- Coating systems

- Flashings and accessories

Our JSC VertiClad is available in a range of profiles, timber species, finishes and coating options to suit a wide variety of aesthetics, features and landscapes.

Key benefits of using JSC VertiClad Vertical Shiplap Weatherboard Cladding System

- Fully tested and CodeMark certified for both flexible and rigid wall underlay options.

- Random width & random width-depth design options.

- Can be custom designed to your specifications including solutions for curved walls.

- Available in a range of profiles, species, and finishes to cater all design requirements.

- In-house factory coating system.

Let us help you with your specification

We've had a longstanding relationship with Masterspec and have been members of Smartspec since its inception in 2012.

Please contact our Architectural business support team for assistance with project-specific specifications.

Technical

FAQ

Frequently Asked Questions

Here you will find answers to some of the most common questions our customers ask about our Cladding Products.

If you don't see your question answered below, please contact us directly for a quick answer - we are always happy to help.

Yes, JSC are happy to provide samples of the species, profile, and even wood oil colours to ensure you get the desired outcome for your build. Send us an email with your request or pop into one of our branches to discuss your requirements!

Yes, JSC has years of experience when it comes to custom and architectural profiles to suit a range of styles and designs. There can be limitations based on things like quantity and weatherproofing considerations so talk to our technical team to discuss options!

Yes, this generally requires a custom weatherboard profile. JSC are specialists when it comes to curved weatherboard solutions so contact our team today to discuss your options.

From New Zealand history, Bevel Back weatherboards are one of the most traditional cladding types in the country, from the bungalows around 1990s, to 1940 -1960s houses, the buildings would typically have this cladding, while villas from the 1880s would be mostly clad in rusticated weatherboards.

Nowadays, Vertical Shiplap weatherboards are considered one of the most popular timber cladding profiles.

For exterior timber JSC always recommends the use of Band Sawn Face over dressed face finish. Band sawn face allows for far greater coating absorption and thus greater lifespan of the chosen coating. As dressed face timbers have the pores of the timber closed off in machining it makes it much harder for coating to penetrate the surface. Today’s bandsawn finishes are much finer than those of previous years and still provide a modern, high quality aesthetic to even the most discerning build.

Yes. We purchase timber from suppliers who have established a clear, verifiable track record in respect of environmental standards and conformance, including legality, sustainability and cultural awareness. This includes JSC being committed to implementing and maintaining the Forest Stewardship Council® (FSC) Chain of Custody requirements for certified timber products as well as recoginsing the importance of promoting the use of responsibly managed timber resources through the Programme Endorsement of Forestry Certification (PEFC). You can find more information here.

We're keen to help you get your hands on a sample of our products. There are 2 ways you can do this:

- Request A Sample - just let us know what products you are interested in and we can ship a sample to you.

- Or, we have a viewing range at our 4 main locations: Auckland, Hamilton, Wellington & Christchurch. Book a time to ensure the right member of our team is available to assist.

JSC products are supplied to trade merchants nationwide, contact our friendly team about your project or product requirements and we would be happy to assist with getting you what you need!

Both JSC Scumble® and JSC Coda® Wood Oils are ideal for timber cladding applications.

JSC Scumble® provides a higher tint coverage while JSC Coda® showcases timber grain with a good penetration into the wood and non-film forming.

Note: Factors such as site exposure, timer species, coating colour, board profile & size, and maintenance all impact on the decision making process. Speak to a JSC rep for guidance in this journey.

- TMT Taiga has rich warm brown tones and “butterfly knots” showing up at regular intervals that give cladding and interiors a completely unique personality.

- TMT Taxon has a soft, even-grained appearance with minimal knots and a variation of deeper chocolate tones.

- While TMT Amba is the lighter, clearer grade option with tonal variation and a similar lighter golden brown tones to TMT Taiga but without the knots.

Yes, for further information on this please see our Codemark certificates available from our downloads section, for each of the main cladding systems.

Assuming you have ordered from JSC, one coating would have been applied to the cladding at the factory, prior to delivery. A second coat can be applied 8 hours AFTER installation.