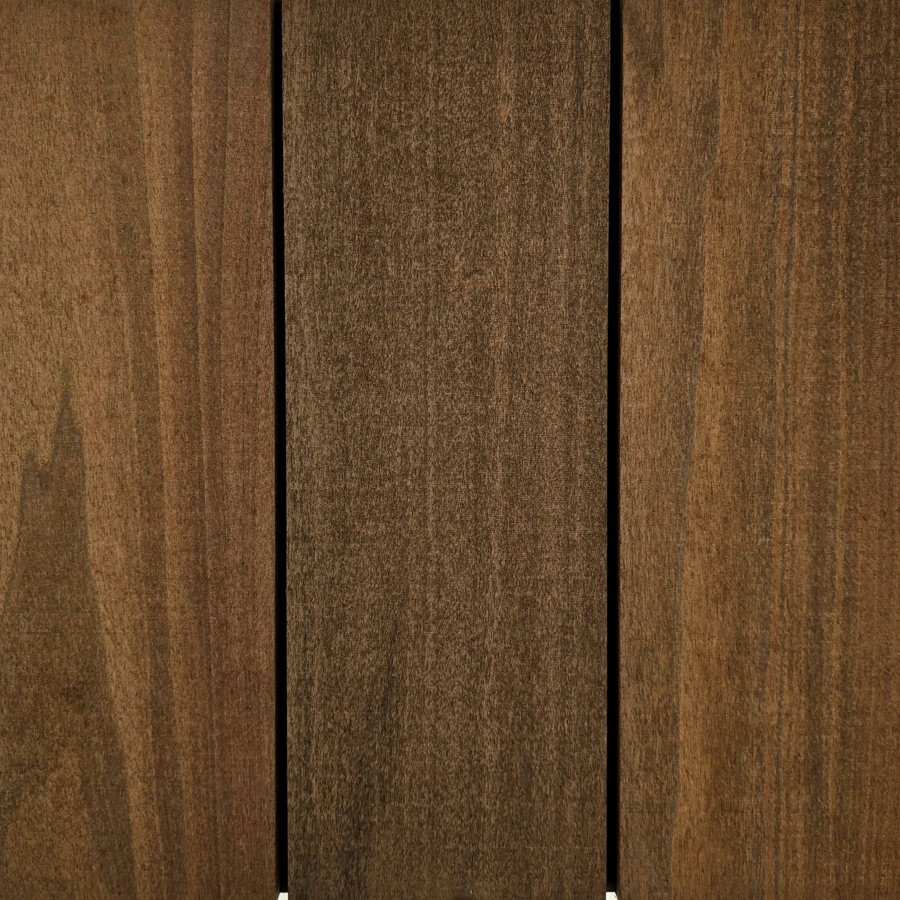

Screens & Battens

A STYLISH TIMBER DESIGN FEATURE BOTH INSIDE AND OUT.

Timber battens or screen walls are an opportunity to inject the beautiful and unique features of natural wood elements to any architectural project which can be used to create visual depth, spatial partitioning, and striking design features within commercial or residential spaces.

JSC stocks a range of species, finishes, and sizes to suit batten and screen designs for both internal and external use.

Photo credits: Sean Park at BEI Group

Available Species

Scope of Use

Interior and exterior options.

Our Projects

The solution for your project

JSC's Timber Screens & Batten Specifications

Exterior Use

In external applications, as they are not part of the weatherproofing membrane, timber battens and screens can be installed at any angle, in variable spacing, and in any style. External screening can be used to create depth within an open space – with wide, broader battens – or privacy and intimacy – with narrower spacing and finer battens. Flexibility in both the design and application leaves the door wide open for architectural innovation and creativity, resulting in a huge range of unique and stylish applications that can be seen across many build and renovation projects in New Zealand.

Interior Use

Internally, timber battens and screens are a popular feature due to their natural aesthetic and warm character, eco-friendly attributes, and their ability to be coated, stained and treated to align with, or contrast against, the wider interior décor. The use of battens in bold horizontal or vertical layouts in partitions, ceilings, walls and balustrades, can create striking architectural features or accents, as well as provide that all-important functional purpose. An extremely popular trend seen in buildings all over the country, timber battens and screens are a stylish, natural feature for any application.

Finish, and available sizes:

Depending on the species and application requirements, timber battens can be provided in both Dressed and Bandsawn finishes. Our most popular sizing – 39x39mm and 45x45mm – is available across most of the JSC range, however our team are happy to discuss any bespoke projects or specifications that you may need.

Common sizes available: 42x42mm; 90x42mm; 140x42mm

Coatings

JSC offers Factory Coatings for all timber battens, as well as fire-retardant coatings for interior applications, to ensure optimal performance and safety. Our expert team can offer advice on the right product and finishing, so contact JSC today to discuss your individual project requirements.

Benefits of Timber Screens & Battens

- Privacy and Division: Create visual barriers for privacy and space division, while maintaining an open feel.

- Aesthetic Warmth: Add a natural and inviting ambiance to spaces, enhancing both interior and exterior aesthetics.

- Light Control: Filter and diffuse natural light, reducing glare and providing a comfortable environment.

- Design Flexibility: Offer customisable patterns and textures, adding visual interest and architectural character.

- Environmental Friendliness: The use of responsibly sourced timber, contributing to eco-friendly design practices.

- Functional Sun Shading: Regulate sunlight and provide shade, improving energy efficiency and comfort.

- Windbreak and Rain Protection: Act as windbreaks and rain screens, enhancing outdoor comfort and extending building life.

- Acoustic Enhancement: Control sound reflections indoors, creating better acoustic environments.

- Biophilic Connection: Integrate natural elements into the built environment, promoting a connection with nature.

These benefits can be applied to both interior and exterior settings, making timber screens and battens versatile design elements for a range of architectural projects.

Technical

FAQ

Frequently Asked Questions

Here you will find answers to some of the most common questions our customers ask about our Battens.

If you don't see your question answered below, please contact us directly for a quick answer - we are always happy to help.

Yes. We purchase timber from suppliers who have established a clear, verifiable track record in respect of environmental standards and conformance, including legality, sustainability and cultural awareness. This includes JSC being committed to implementing and maintaining the Forest Stewardship Council® (FSC) Chain of Custody requirements for certified timber products as well as recoginsing the importance of promoting the use of responsibly managed timber resources through the Programme Endorsement of Forestry Certification (PEFC). You can find more information here.

If coating is to be applied, JSC will always offer this as a Dressed & sanded supply. This is because dressed face timbers close the pores of the timber, meaning coatings sit on the surface rather than absorbing into the fibre, causing delays and potential coating consistency issues. Drying times can also be further reduced by specifying JSC Scumble & Coda coating products. Speak to a JSC representative about the best surface finish and coating options for your specific project.

- TMT Taiga has rich warm brown tones and “butterfly knots” showing up at regular intervals that give cladding and interiors a completely unique personality.

- TMT Taxon has a soft, even-grained appearance with minimal knots and a variation of deeper chocolate tones.

- While TMT Amba is the lighter, clearer grade option with tonal variation and a similar lighter golden brown tones to TMT Taiga but without the knots.

Enhanced durability and exceptional dimensional stability

Able to accept darker coatings with a significant reduction in dimensional movement

Low susceptibility to fungal decay

Consistent, aesthetically pleasing colour

Easily workable and easy to maintain

Thermal modification is an environmentally friendly process resulting in an exceptionally stable, highly durable, and aesthetically pleasing timber – all desirable properties for bespoke cladding profiles.

Thermal modification is a conceptually simple process - suitable timbers are subjected to high temperatures using heat and steam in a controlled environment without the use of any chemicals. Once the process is complete, the equilibrium moisture percentage of the modified product is around 4-7%.

The thermal modification process permanently alters the cell structure which enhances the physical properties of the timber. The result of this is that the timber has a greatly reduced capacity to absorb moisture. With the reduction of moisture absorption, the timber is much less susceptible to cupping, expansion, contraction, or distortion caused by seasonal changes in the environment. Due to the thermally modified process that the timbers undergo, all the sugars and tannins in the wood are baked, removing the food source from fungi and insects as well as hardening and darkening the wood. You will see all TMT options come in rich brown tones and are suitable for a variety of interior and exterior applications such as exterior claddings, interior linings, battens, and more depending on the species you choose

Yes, JSC are happy to provide samples of the species, profile, and even wood oil colours to ensure you get the desired outcome for your build. Send us an email with your request or pop into one of our branches to discuss your requirements!

We're keen to help you get your hands on a sample of our products. There are 2 ways you can do this:

- Request A Sample - just let us know what products you are interested in and we can ship a sample to you.

- Or, we have a viewing range at our 4 main locations: Auckland, Hamilton, Wellington & Christchurch. Book a time to ensure the right member of our team is available to assist.

JSC products are supplied to trade merchants nationwide, contact our friendly team about your project or product requirements and we would be happy to assist with getting you what you need!