Search

Your search for "" returned:

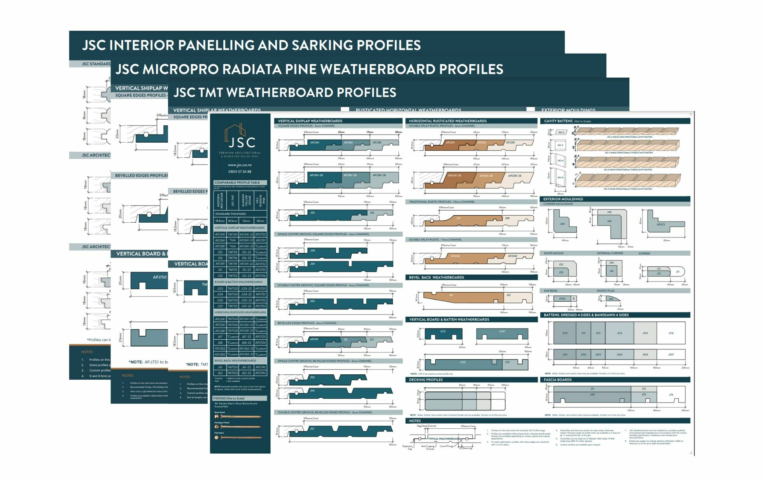

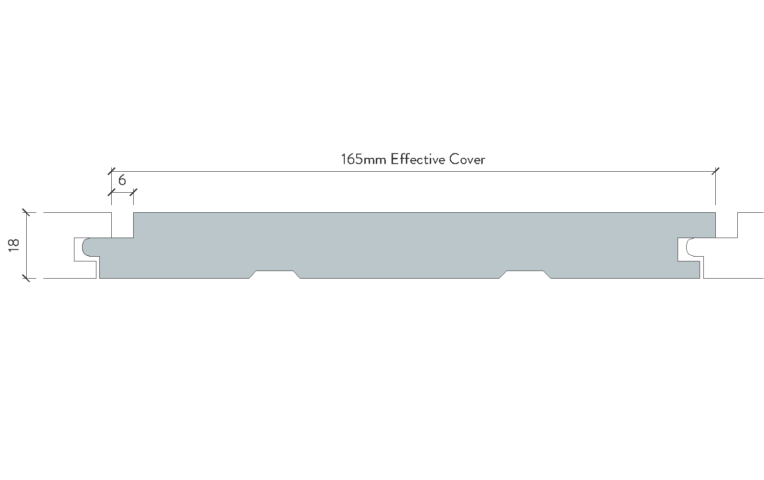

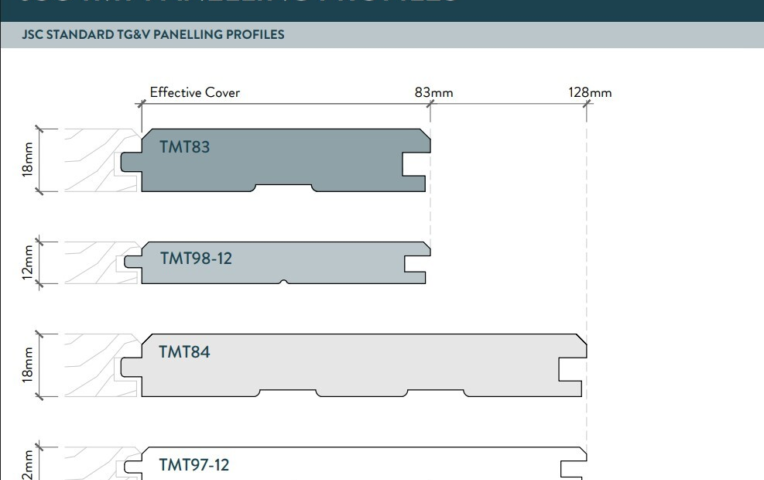

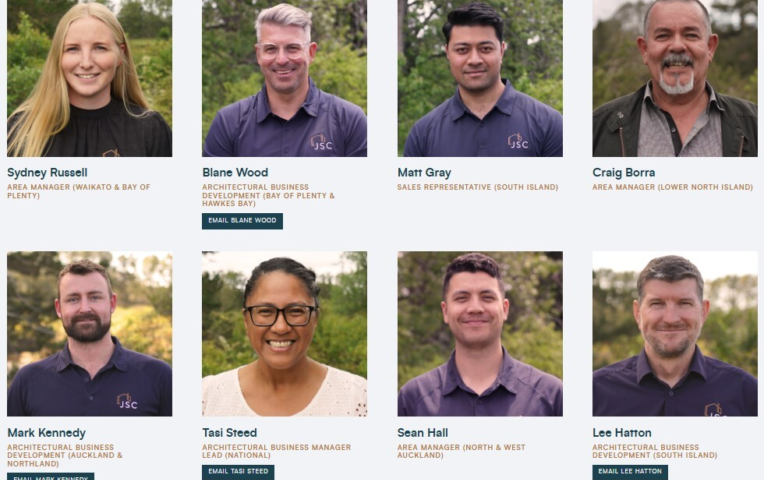

Profiles

Technical Documents

FAQ

Frequently Asked Questions

You may find the information you're looking for in these FAQs.

Hardwood decking should be cleaned annually. Use a soft brush with water and mild detergent. Do not direct high pressure water on any part of the hardwood timber. Where a coating is applied, periodic recoating is required to ensure its integrity is sustained. Follow the manufacturer’s instructions regarding hardwood chemical runoff. The amount and characteristics of the runoff will depend on the species, dryness of the boards when installed and how exposed the deck is to the weather.

Assuming you have ordered from JSC, one coating would have been applied to the cladding at the factory, prior to delivery. A second coat can be applied 8 hours AFTER installation.

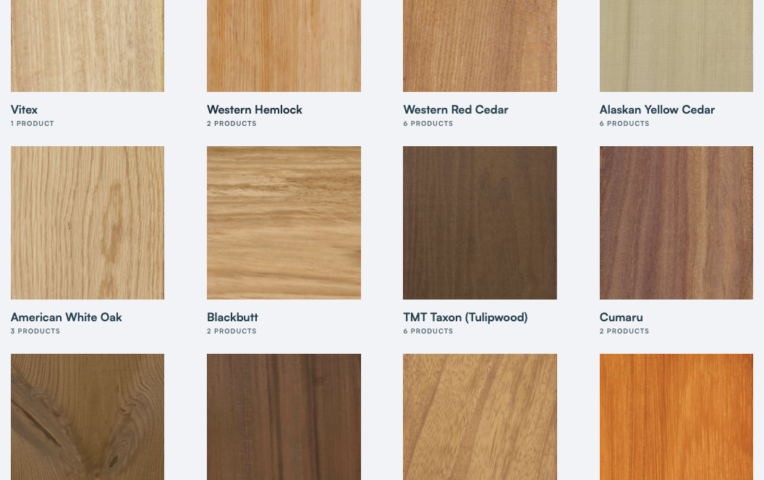

JSC products are supplied to trade merchants nationwide, contact our friendly team about your project or product requirements and we would be happy to assist with getting you what you need!

We're keen to help you get your hands on a sample of our products. There are 2 ways you can do this:

- Request A Sample - just let us know what products you are interested in and we can ship a sample to you.

- Or, we have a viewing range at our 4 main locations: Auckland, Hamilton, Wellington & Christchurch. Book a time to ensure the right member of our team is available to assist.

Yes. We purchase timber from suppliers who have established a clear, verifiable track record in respect of environmental standards and conformance, including legality, sustainability and cultural awareness. This includes JSC being committed to implementing and maintaining the Forest Stewardship Council® (FSC) Chain of Custody requirements for certified timber products as well as recoginsing the importance of promoting the use of responsibly managed timber resources through the Programme Endorsement of Forestry Certification (PEFC). You can find more information here.

On average, recoating is required every 2 to 4 years. JSC Scumble - typically every 3-5* years while JSC Coda would be typically 2-3 years*. The timeframes would be affected by factors such as:

Weather/UV exposure/Humidity

Site location and orientation

Timber species

Coating colour

Restricted light and air flow

Proximity to vegetation and airborne contaminants

Maintenance frequency

Pencil marks can prove difficult to remove on some coatings, always start with the lightest cleaning method, a light detergent and a stiff brush (like a fingernail brush) and brush in the direction of the grain. Using an eraser may help but can risk making a smooth spot on the board. If this occurs on bandsawn face timbers then a stainless steel wire brush can help to roughen up the texture again before a second coat is applied.

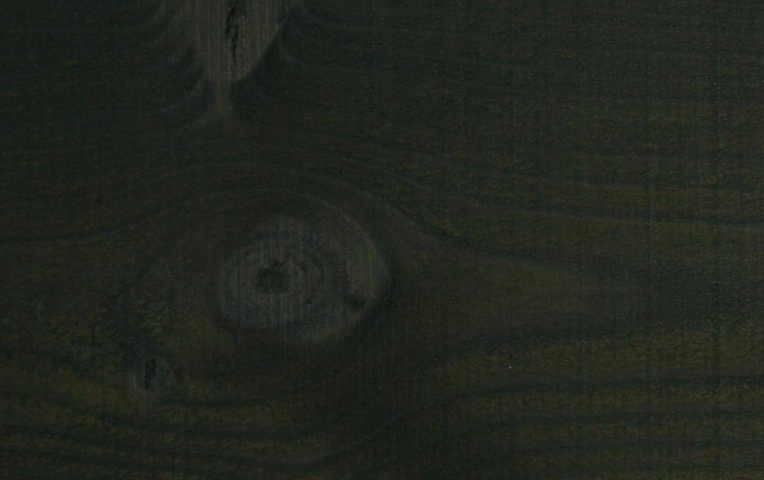

Yes, as long as you are using the same base oil i.e JSC Scumble over JSC Scumble or JSC Coda over JSC Coda then a darker coating can be applied. Always check with JSC first to confirm that the colour is suitable for your chosen timber and profile as some timbers can not handle the heat that comes with darker colours. We always recommend doing a test sample on an offcut piece of timber where possible to confirm colour is as desired.

Yes a clear oil can be applied over the initial colour coat of woodoil. We always recommend doing a test sample on an offcut piece of timber where possible to confirm colour is as desired.

For spray equipment, brushes, and clothes; clean with hot water. Use a wiping rag with hot water on smooth surfaces and a brush on rough surfaces to clean over-spray or accidental spillage. If brushes remain clogged, rinse with Isopropyl alcohol.

Hardwood decking typically does not require a coating. However, when the right coating is selected, correctly applied, and properly maintained, coating can help minimise surface checking, reduce cupping, and slow the silvering process. If you want to coat your deck we recommend that a “clear” decking oil is used. Do not use linseed oil based products, as it can facilitate mould and fungal growth. Clear oil coating won’t prevent decking from silvering/ greying-off. JSC offers a factory-applied coating option to speed up application. Cut ends need to be coated during installation. Boards should be free of all surface marks and stains before coating. Always follow the manufacturer’s guidelines for cleaning, application, and drying

JSC Coda Wood Oil can be used on decking. Coating for decking is only recommended in our clear coating option.

In standard climates and on commonly used kinds of timber species:

· Touch-dry: 3 hours

· Workable: 8 hours

The drying process can be markedly delayed in unfavorable weather conditions (high humidity, low temperatures, minimal air movement). The drying time can also vary depending on the type of wood.

Dressed surface: You can use a PAL Speedbrush or a short nap roller.

Band Sawn surface: You can use a wide bristle brush or a medium nap roller.

Another option is to use airless spray equipment (choose a nozzle to deliver a low-pressure coarse spray).

We strongly recommend reading the JSC Coatings Application, Maintenance and Recoating guide for detailed information on this.

For paint finish:

all sharp edges must be removed to provide a radius to minimize stress on the paint film

nails are to be punched and the holes to be primed promptly,

fill holes with a suitable filler

filled holes to be primed again and sanded once dry.

For detailed instructions please refer to Cladding Installation and Specification Guide.

The optimal weather conditions are dry weather with a minimum temperature of 13°C. If possible, avoid direct sunlight and high temperatures, so overcast days are ideal.

Do not apply coatings when the substrate moisture content exceeds 18%.

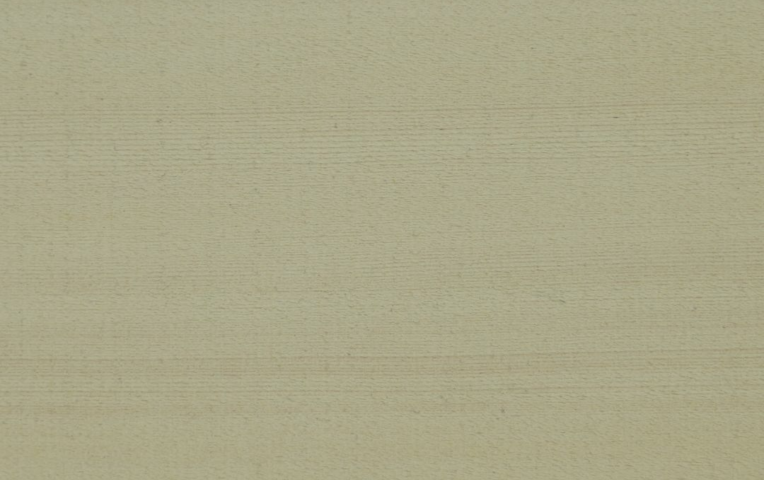

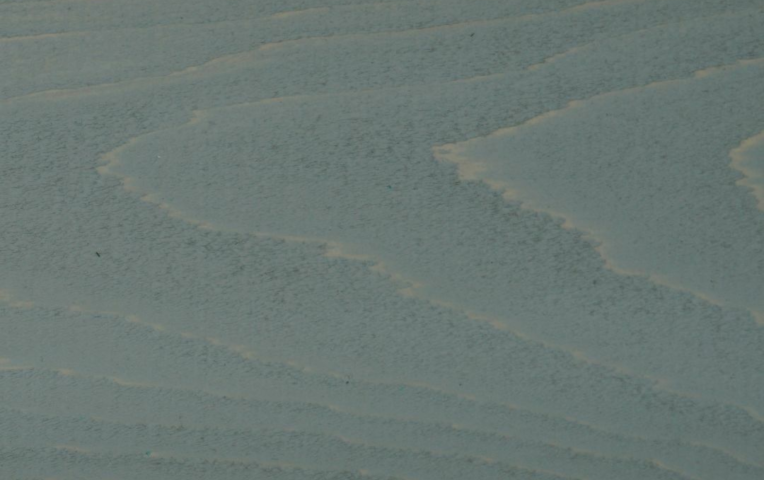

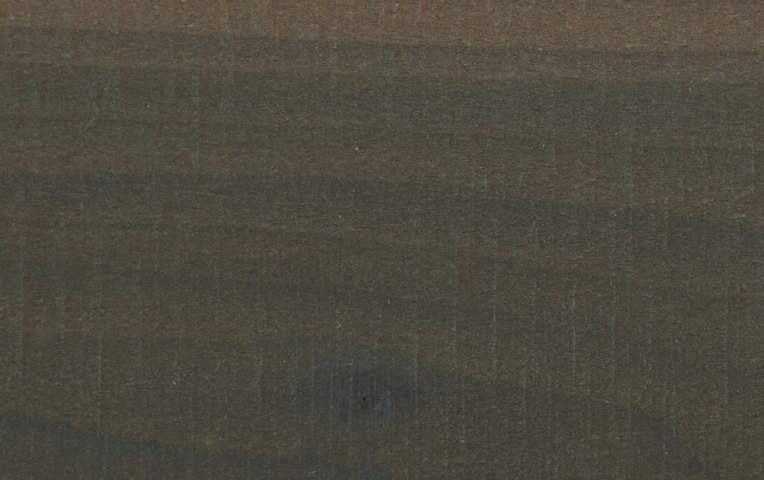

Both JSC Scumble® and JSC Coda® Wood Oils are ideal for timber cladding applications.

JSC Scumble® provides a higher tint coverage while JSC Coda® showcases timber grain with a good penetration into the wood and non-film forming.

Note: Factors such as site exposure, timer species, coating colour, board profile & size, and maintenance all impact on the decision making process. Speak to a JSC rep for guidance in this journey.

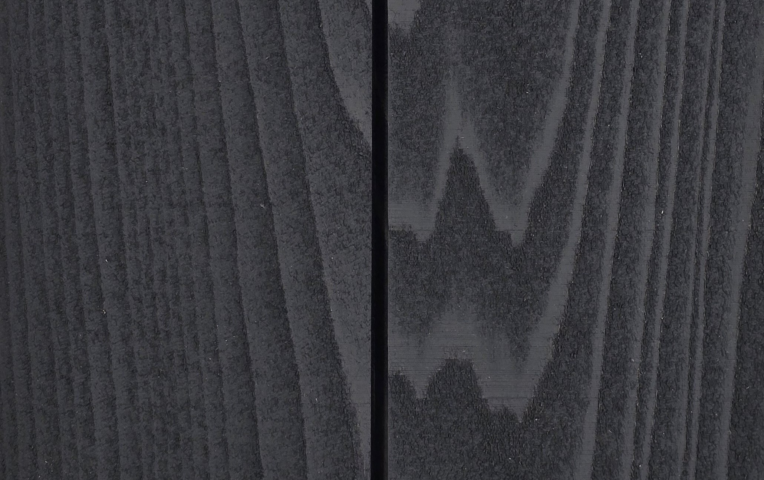

For exterior timber JSC always recommends the use of Band Sawn Face over dressed face finish. Band sawn face allows for far greater coating absorption and thus greater lifespan of the chosen coating. As dressed face timbers have the pores of the timber closed off in machining it makes it much harder for coating to penetrate the surface. Today’s bandsawn finishes are much finer than those of previous years and still provide a modern, high quality aesthetic to even the most discerning build.

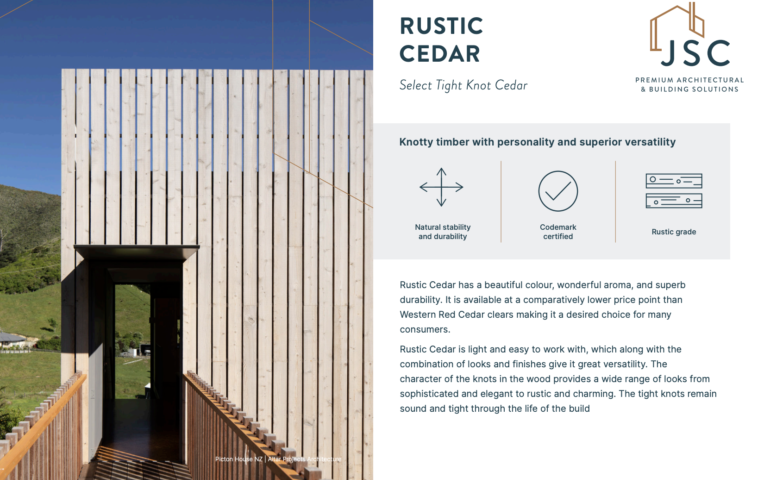

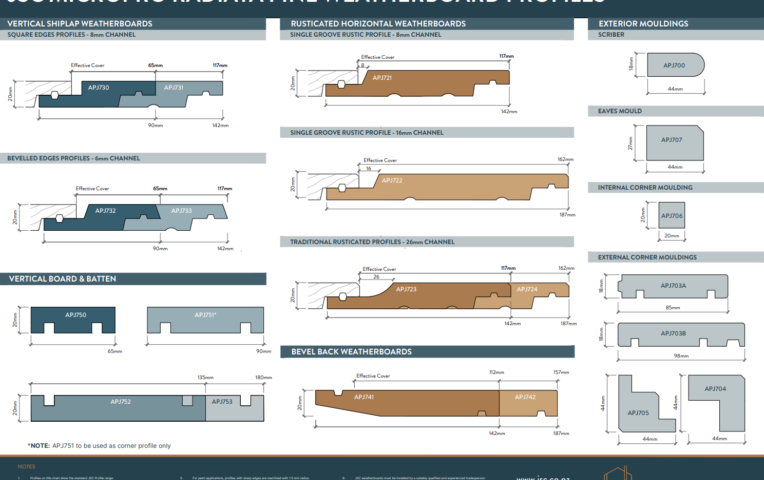

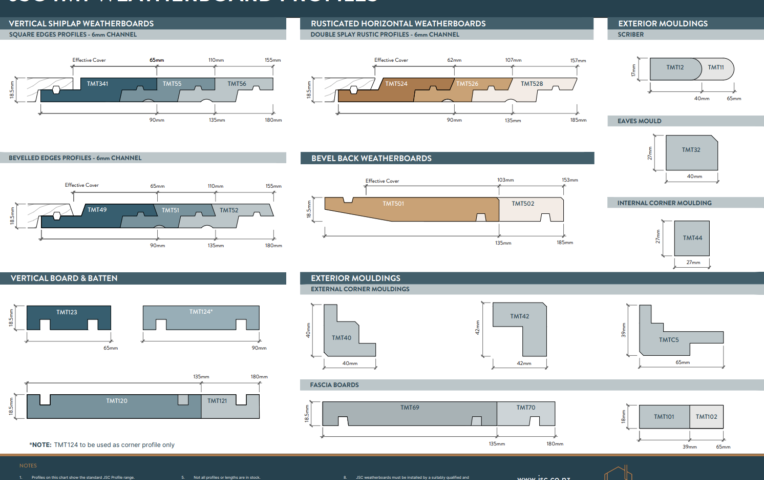

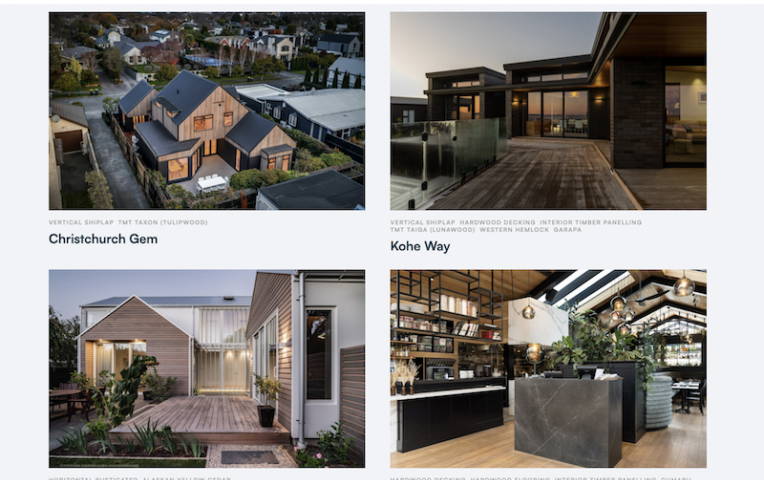

From New Zealand history, Bevel Back weatherboards are one of the most traditional cladding types in the country, from the bungalows around 1990s, to 1940 -1960s houses, the buildings would typically have this cladding, while villas from the 1880s would be mostly clad in rusticated weatherboards.

Nowadays, Vertical Shiplap weatherboards are considered one of the most popular timber cladding profiles.

Yes, this generally requires a custom weatherboard profile. JSC are specialists when it comes to curved weatherboard solutions so contact our team today to discuss your options.

Yes, JSC has years of experience when it comes to custom and architectural profiles to suit a range of styles and designs. There can be limitations based on things like quantity and weatherproofing considerations so talk to our technical team to discuss options!

Yes, JSC are happy to provide samples of the species, profile, and even wood oil colours to ensure you get the desired outcome for your build. Send us an email with your request or pop into one of our branches to discuss your requirements!

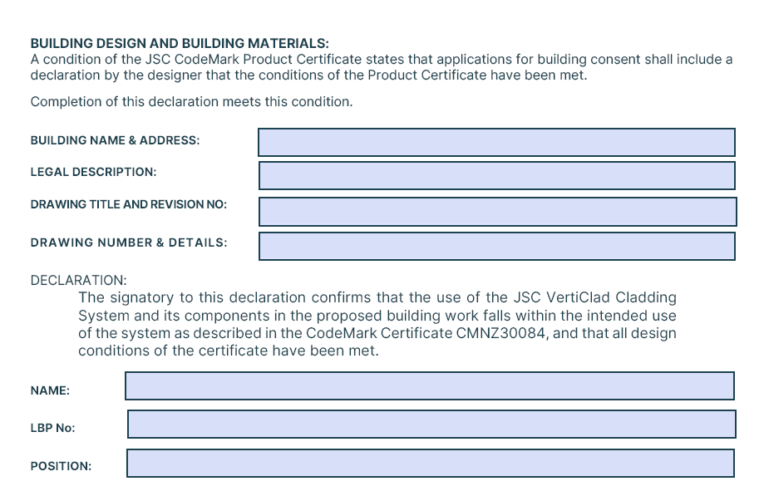

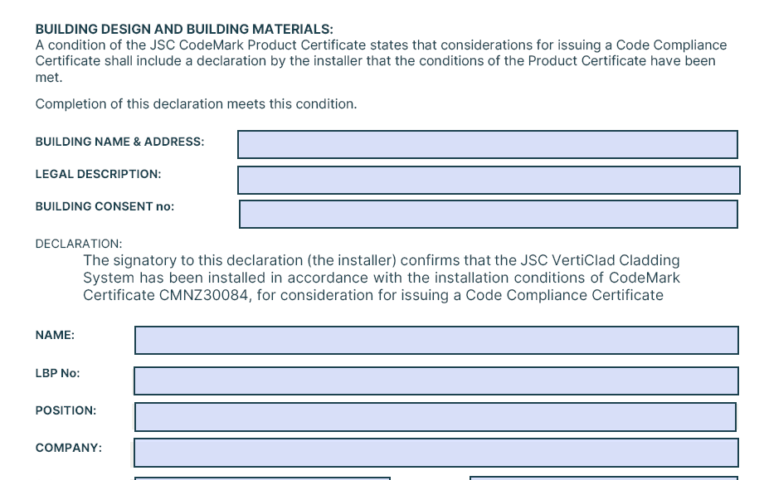

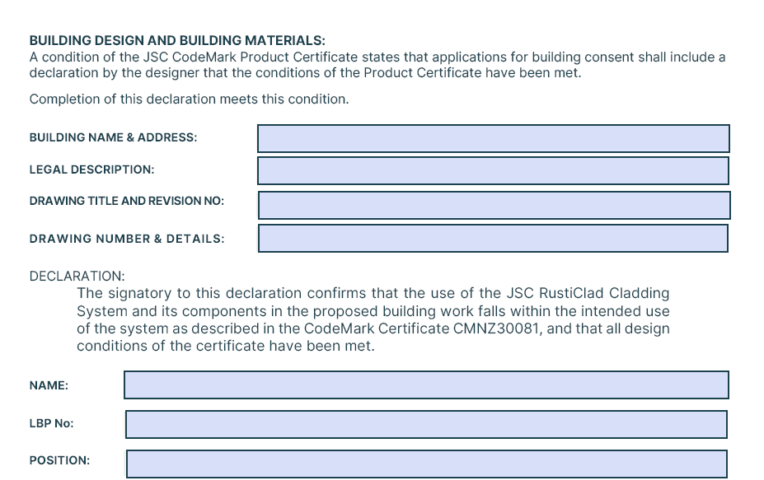

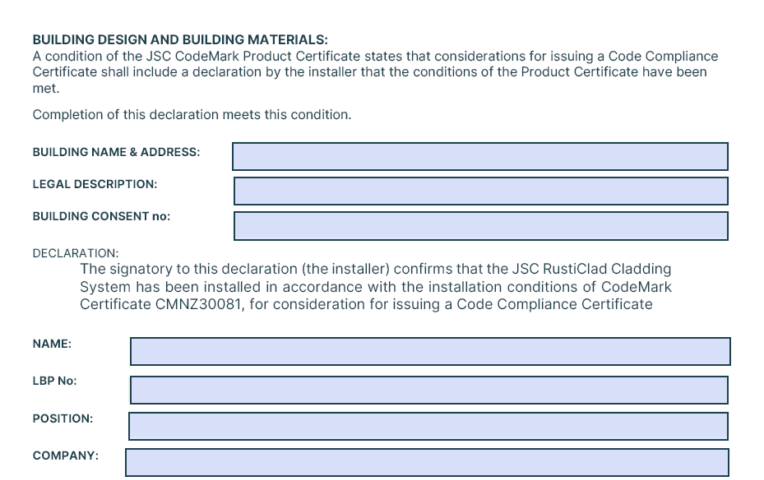

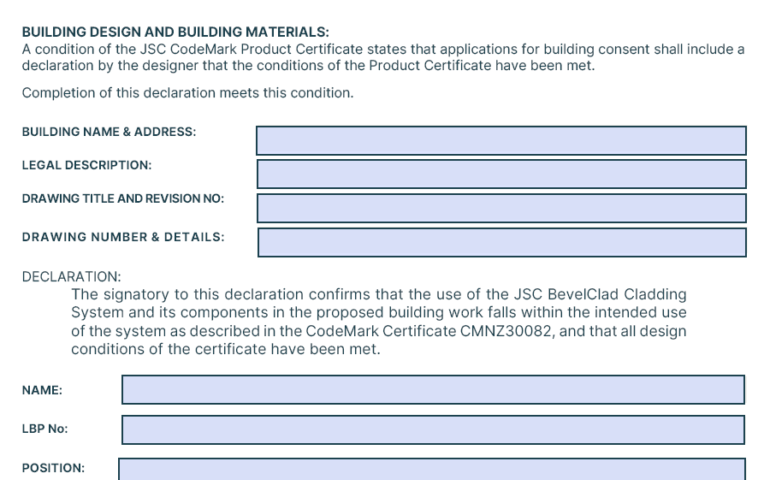

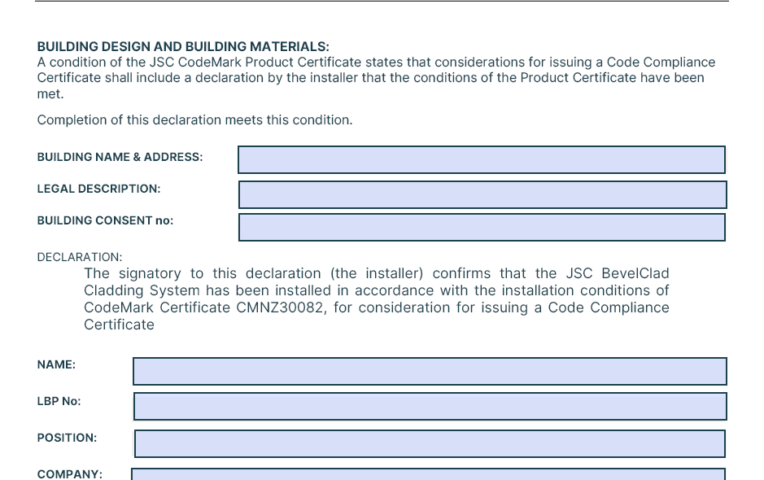

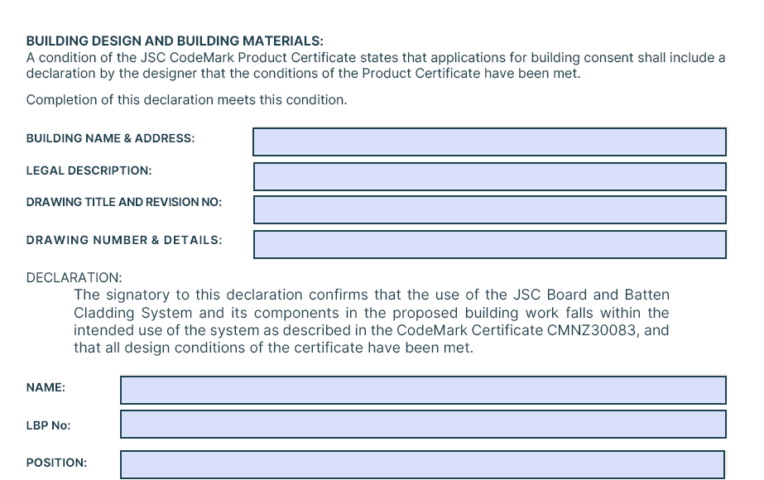

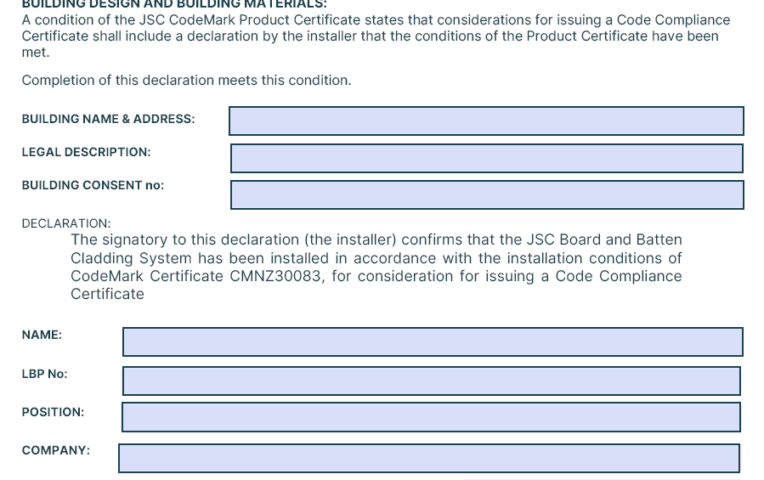

Yes, for further information on this please see our Codemark certificates available from our downloads section, for each of the main cladding systems.

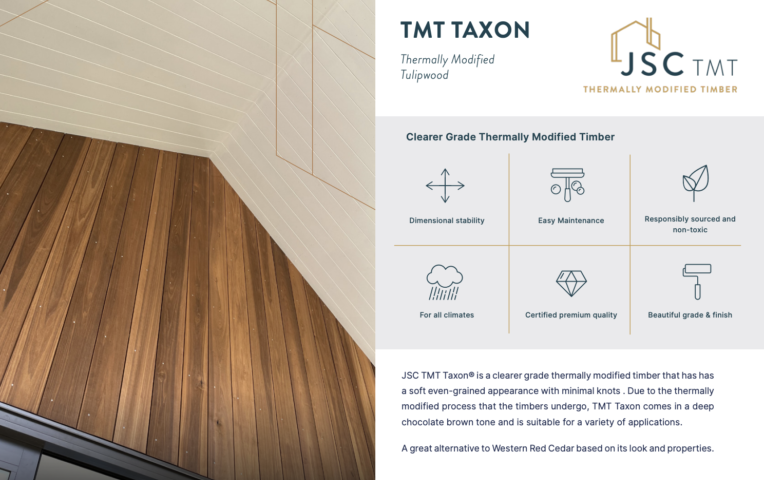

Thermal modification is an environmentally friendly process resulting in an exceptionally stable, highly durable, and aesthetically pleasing timber – all desirable properties for bespoke cladding profiles.

Thermal modification is a conceptually simple process - suitable timbers are subjected to high temperatures using heat and steam in a controlled environment without the use of any chemicals. Once the process is complete, the equilibrium moisture percentage of the modified product is around 4-7%.

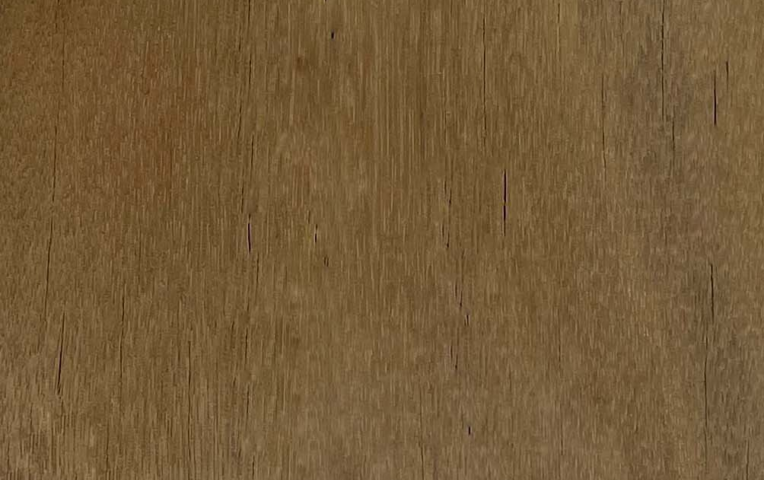

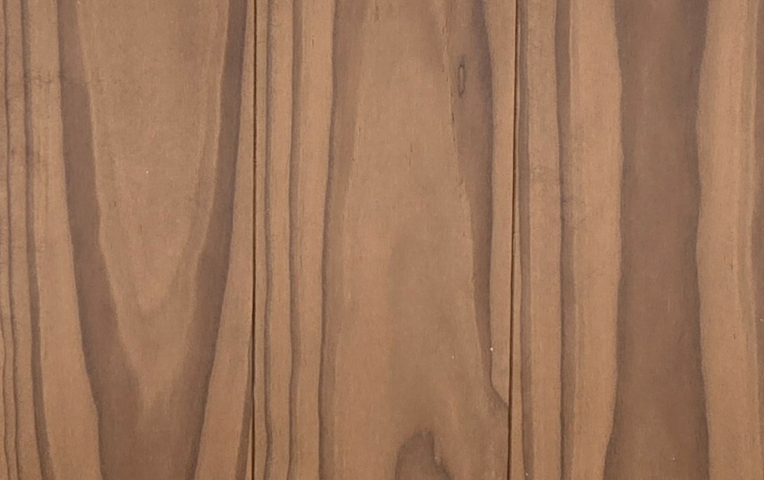

The thermal modification process permanently alters the cell structure which enhances the physical properties of the timber. The result of this is that the timber has a greatly reduced capacity to absorb moisture. With the reduction of moisture absorption, the timber is much less susceptible to cupping, expansion, contraction, or distortion caused by seasonal changes in the environment. Due to the thermally modified process that the timbers undergo, all the sugars and tannins in the wood are baked, removing the food source from fungi and insects as well as hardening and darkening the wood. You will see all TMT options come in rich brown tones and are suitable for a variety of interior and exterior applications such as exterior claddings, interior linings, battens, and more depending on the species you choose

Enhanced durability and exceptional dimensional stability

Able to accept darker coatings with a significant reduction in dimensional movement

Low susceptibility to fungal decay

Consistent, aesthetically pleasing colour

Easily workable and easy to maintain

Yes, like any other timber, the thermally modified timber cladding has to be sealed on all four sides before installation.

Yes. Thermal modification is an environmentally friendly process. It is a chemical-free process that uses only heat and steam.

Yes. The thermal modification process does not change the combustibility of the timber.

- Dimensional stability - Excellent dimensional stability through reduced moisture absorption and modified cell structure. Able to accept darker coatings with significant reduction in dimensional movement.

- Durability - Proven durability through a lowered moisture content and the removal of the food source during the TMT process, ensures low susceptibility to fungal decay.

- Responsibly sourced and non-toxic - Premium quality that is responsibly sourced. There is no presence or release of added toxic substances during the building life.

- Certified premium quality - Truly natural product with certified quality; all JSC TMT® products are sourced from reliable and world-renowned suppliers that are leaders in the timber thermal modification process.

- For all climates - Proven to work well, even in the most challenging climates. More stable in humid conditions.

- Beautiful grade & finish - Whether a feature or clearer grade, all JSC TMT® options come in beautiful rich brown tones and take oil and water-based coatings well, including dark colours.

Thermal modification is a conceptually simple process - suitable timbers are subjected to high temperatures using heat and steam in a controlled environment without the use of any chemicals. Once the process is complete, the equilibrium moisture percentage of the modified product is around 4-7%.

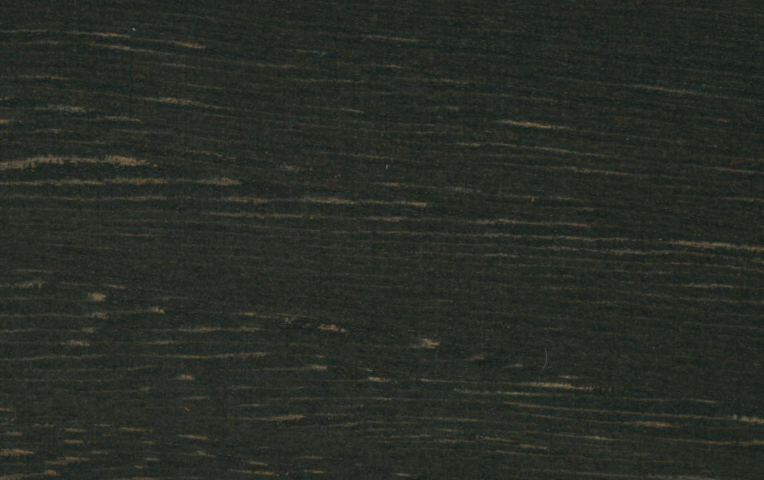

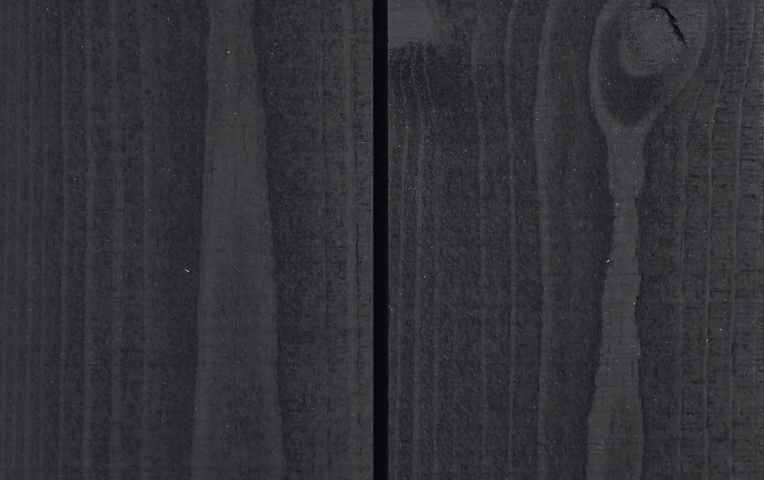

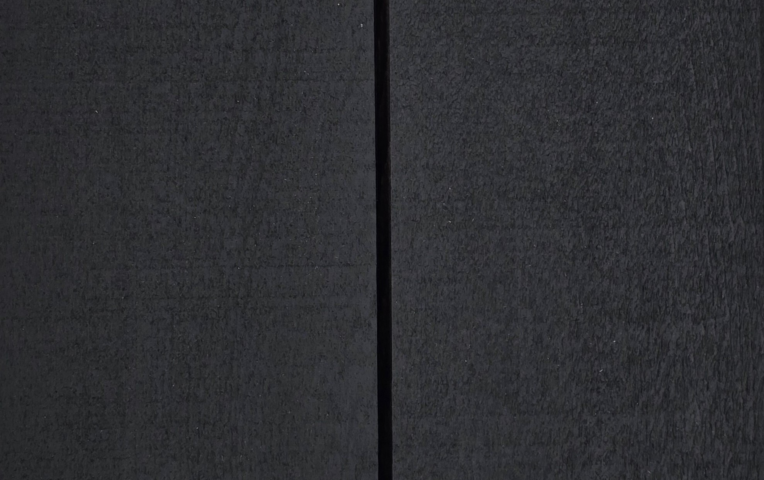

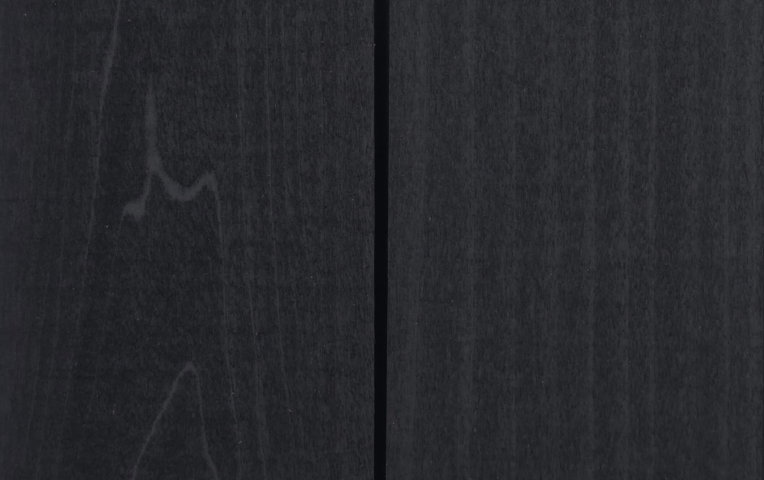

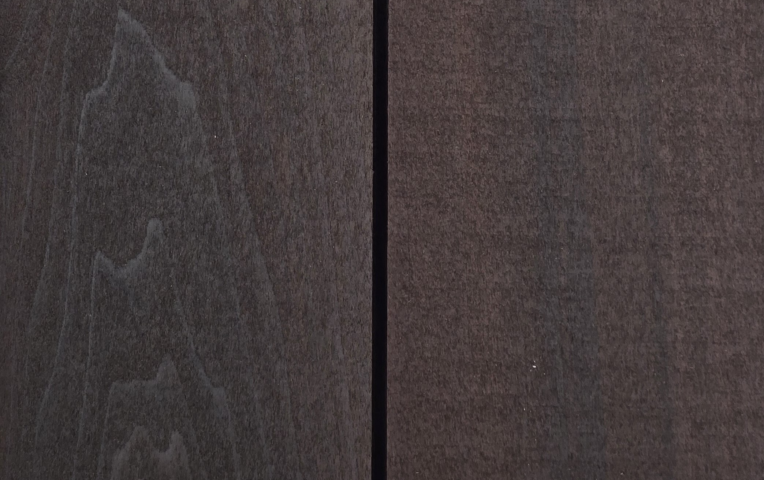

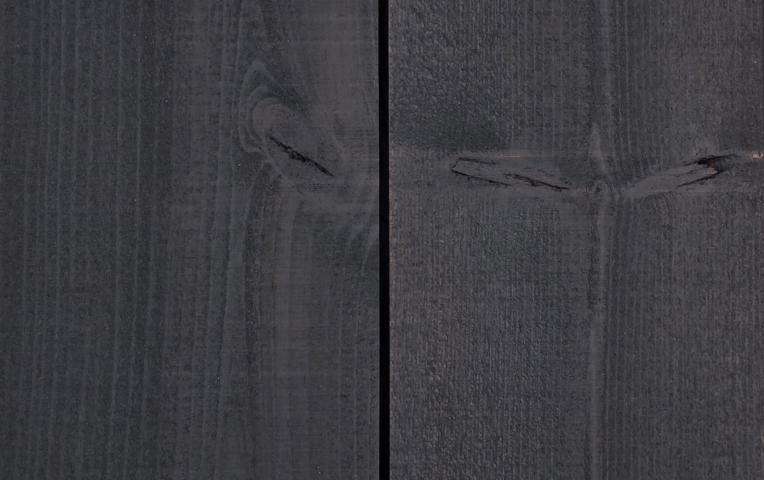

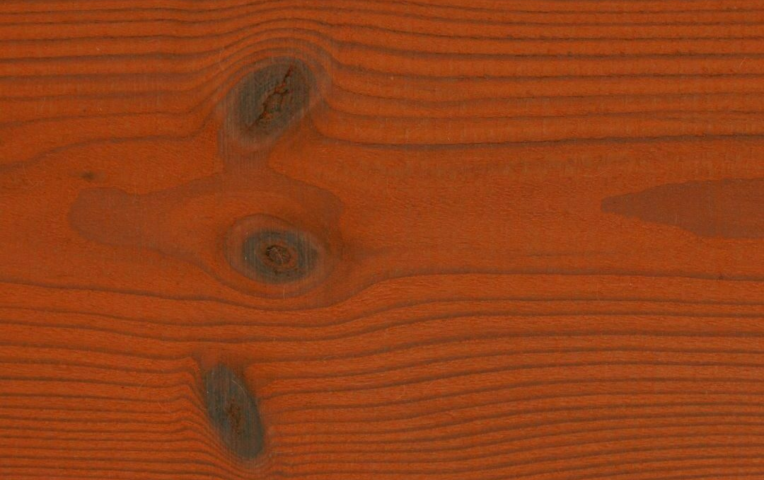

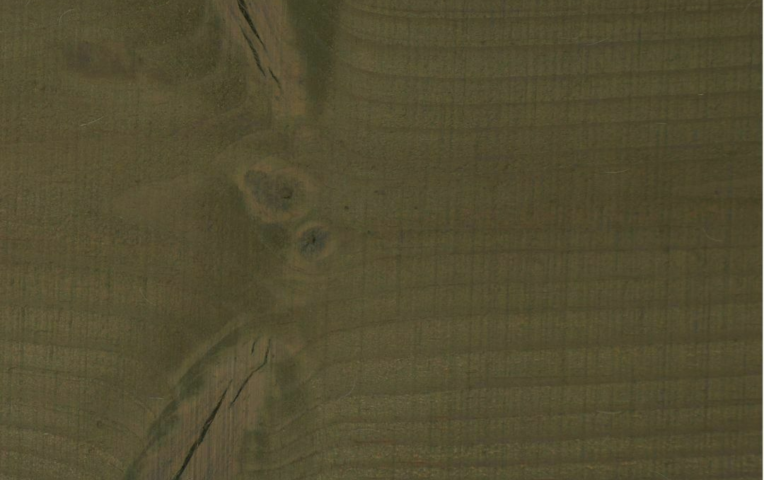

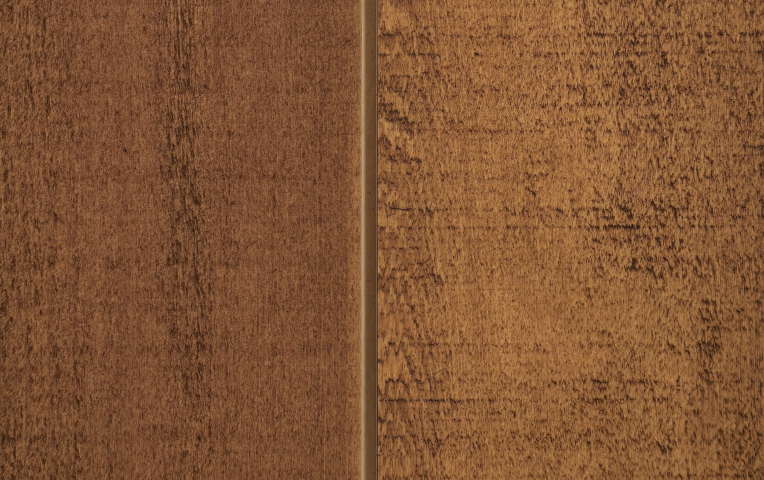

- TMT Taiga has rich warm brown tones and “butterfly knots” showing up at regular intervals that give cladding and interiors a completely unique personality.

- TMT Taxon has a soft, even-grained appearance with minimal knots and a variation of deeper chocolate tones.

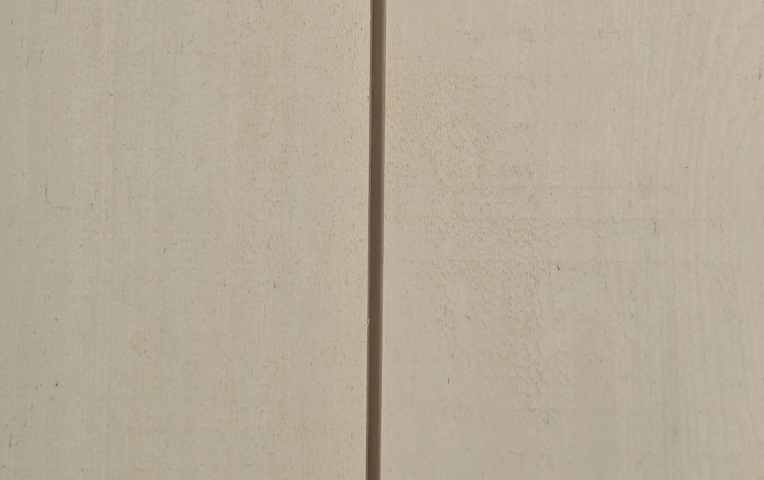

- While TMT Amba is the lighter, clearer grade option with tonal variation and a similar lighter golden brown tones to TMT Taiga but without the knots.

Establish a regular cleaning routine to prevent dirt and debris from scratching the surface of the boards. Use only recommended cleaning solutions and avoid getting water on the floor. Do not use harsh detergents and avoid using any abrasive materials to clean the hardwood flooring.

Yes. After the construction operations are complete, acclimatise the flooring by stacking it in the in-service conditions for a minimum period of two weeks with air circulation to all surfaces as follows:

Air conditioning operational

Lighting operational

Site drainage works are complete

Space fully enclosed and secure

Wet work complete and dry

45+ LRV Paint colour only - no dark colours. Speak to a JSC representative about colour options including stain colours.

If coating is to be applied, JSC will always offer this as a Dressed & sanded supply. This is because dressed face timbers close the pores of the timber, meaning coatings sit on the surface rather than absorbing into the fibre, causing delays and potential coating consistency issues. Drying times can also be further reduced by specifying JSC Scumble & Coda coating products. Speak to a JSC representative about the best surface finish and coating options for your specific project.

Yes absolutely. Our reps dedicate several days each week to visiting our customers. Simply contact us and we can book that in.

Absolutely. Our manufacturing hub is located in Auckland and our trucks are delivering local daily. Contact us for your competitive quote.

For sure. We offer our full range from Cladding, Decking, Panelling, Screens, Battens, Thermally Modified Timber, Flooring and the supporting system fittings for each system for our Wellington customers. Contact us to find out more.

Yes absolutely. Our reps dedicate several days each week to visiting our customers. Simply contact us and we can book that in.

For sure. We offer our full range from Cladding, Decking, Panelling, Screens, Battens, Thermally Modified Timber, Flooring and the supporting system fittings for each system for our South Island customers. Contact us to find out more.

Absolutely. Our manufacturing hub is located in Auckland and our trucks are delivering local daily. Contact us for your competitive quote.

Yes absolutely. Our reps dedicate several days each week to visiting our customers. Simply contact us and we can book that in.

For sure. We offer our full range from Cladding, Decking, Panelling, Screens, Battens, Thermally Modified Timber, Flooring and the supporting system fittings for each system for our Auckland customers. Contact us to find out more.

Absolutely. Our manufacturing hub is located in Auckland and our trucks are delivering local daily. Contact us for your competitive quote.

Yes absolutely. Our reps dedicate several days each week to visiting our customers. Simply contact us and we can book that in.

For sure. We offer our full range from Cladding, Decking, Panelling, Screens, Battens, Thermally Modified Timber, Flooring and the supporting system fittings for each system for our Waikato & Bay of Plenty customers. Contact us to find out more.

Absolutely. Our manufacturing hub is located in Auckland and our trucks are delivering local daily. Contact us for your competitive quote.

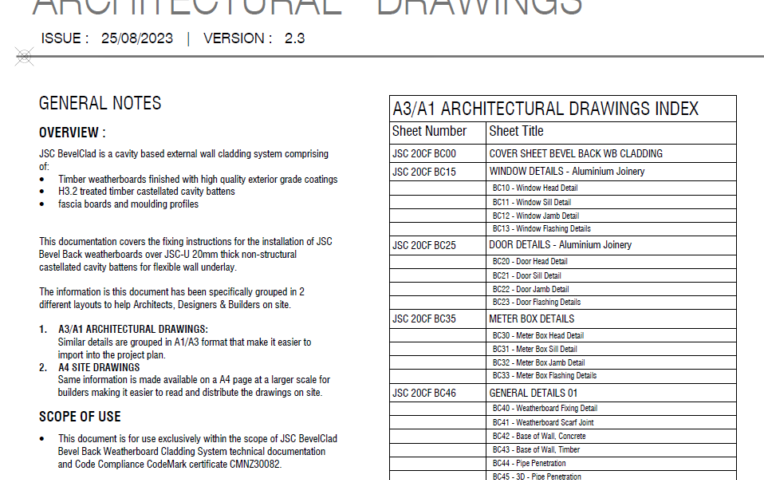

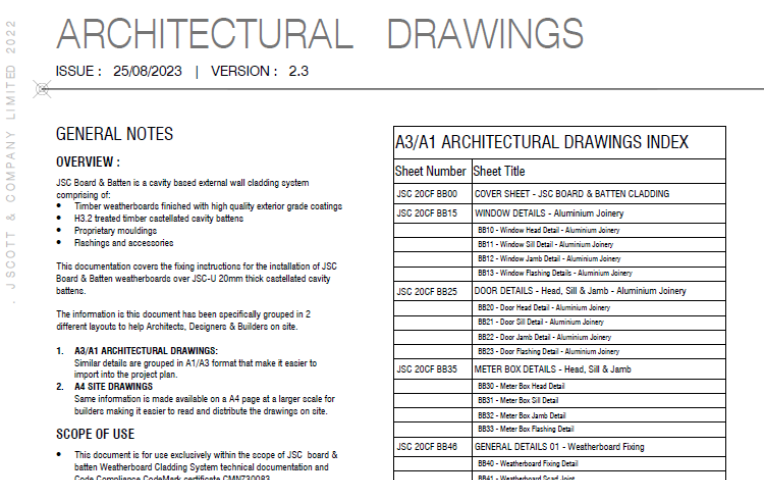

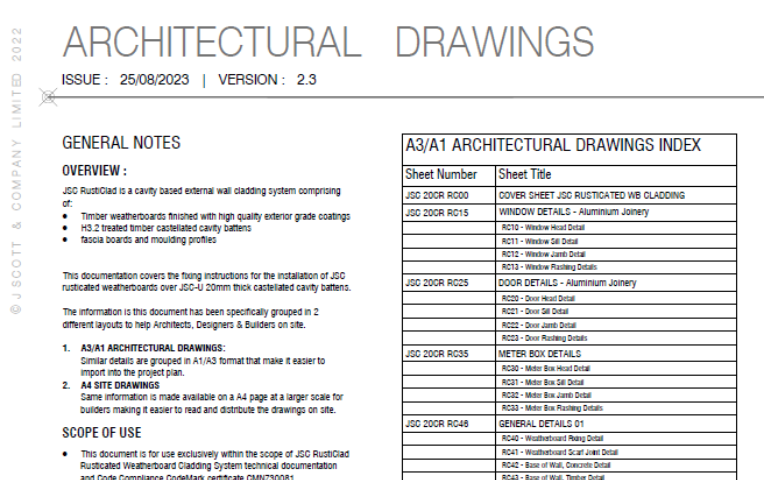

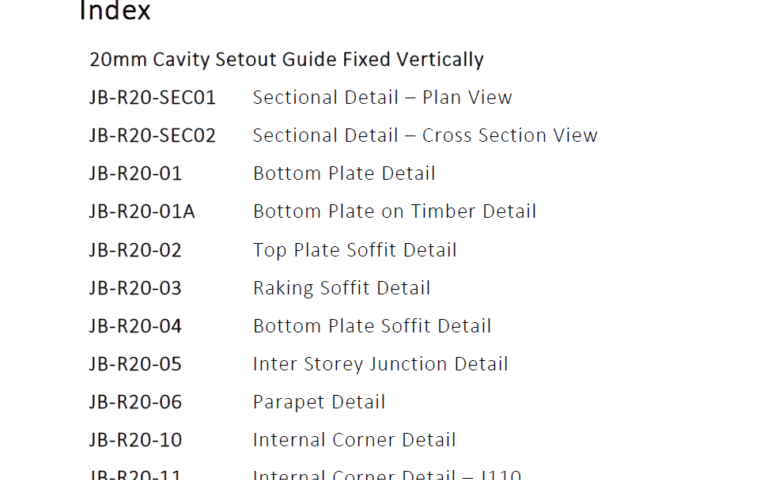

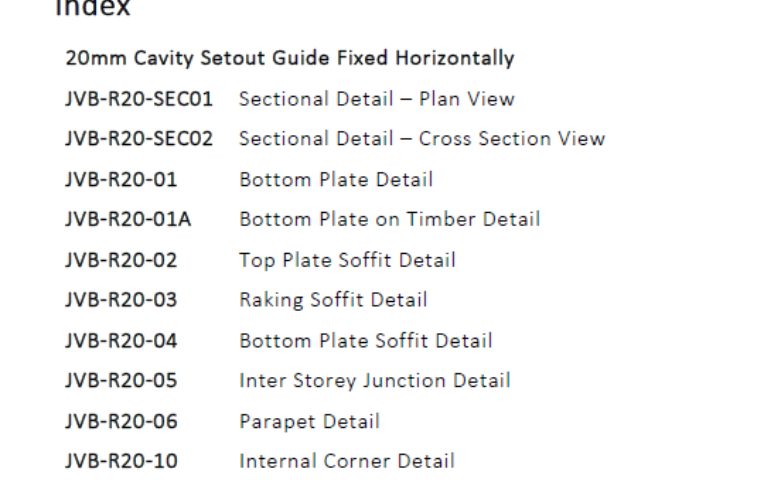

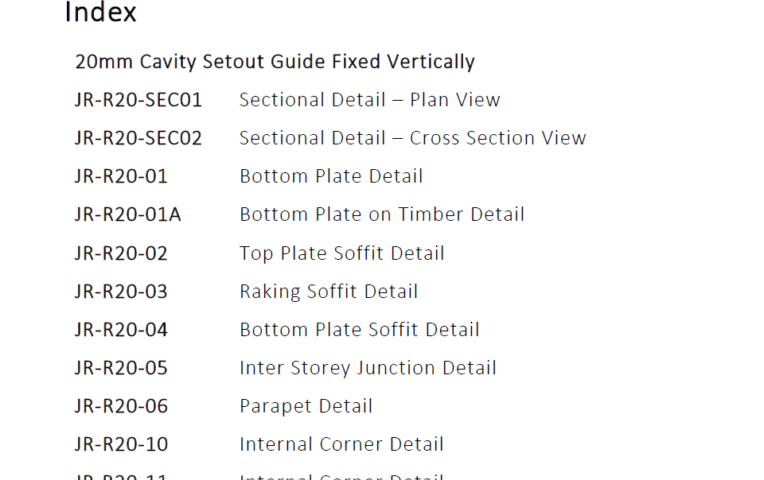

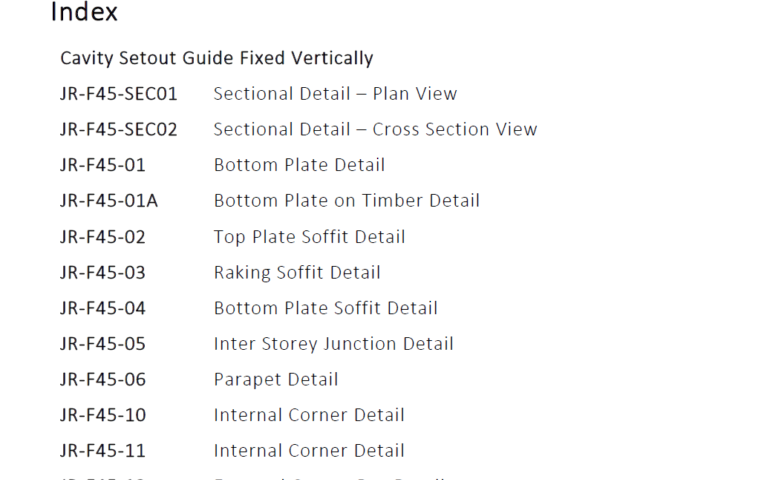

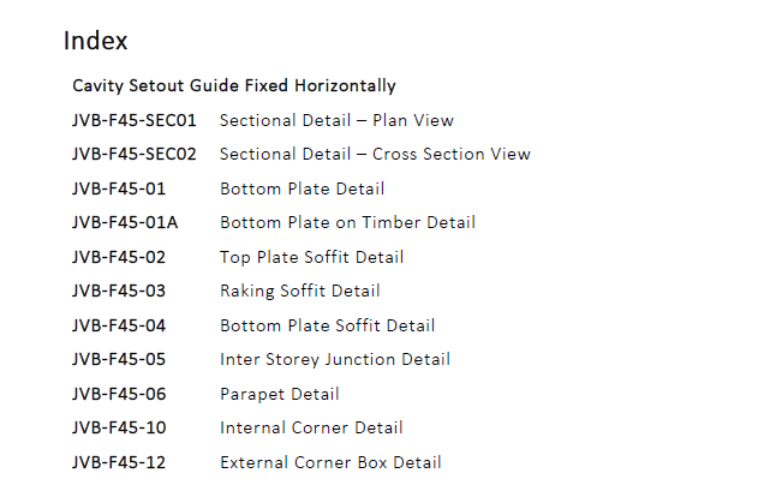

The technical drawings are exactly the same on both sets. The main difference between them lies in their layout and purpose:

- A3/A1 Architectural Drawings:

These drawings group similar details together on larger A1 or A3 pages. They are designed to make it easier for architects, designers and specifiers to access and reference grouped details. For instance, all window details, meter box details, and corner details might be presented together on a single A1 or A3 page.

- A4 Site Drawings:

Each detail is presented on individual A4 pages. These drawings are specifically tailored for builders on-site. The larger scale of each detail on its own A4 page makes it easier to read and distribute the drawings at the construction site.

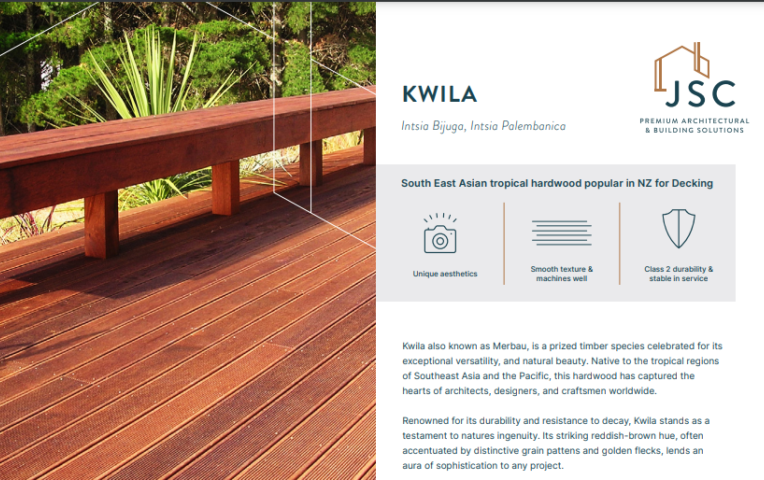

Kwila is well-suited to New Zealand's climate, offering excellent resistance to decay and weathering, making it a popular choice for outdoor decking.

- Regularly sweep or use a leaf blower to clear away dirt and leaf build-up. Pay special attention to maintaining gaps between boards, especially over joists, to prevent debris from accumulating and retaining moisture.

- Inspect at least annually, check for signs of wear, rot, or damage.

- Re-coat as recommended by the coating manufacturer, following their specified timeframes and application instructions.

To prevent moisture build-up that can lead to discolouration or rotting, move potted plants or objects placed directly on the deck periodically, or elevate them to avoid prolonged direct contact with the decking. These items can trap moisture underneath, preventing the timber from drying out properly.

Yes, JSC's Kwila has been a subject of environmental concern due to illegal logging practices in some regions, leading to deforestation and negative impacts on local ecosystems. However, at JSC, we ensure that our Kwila is responsibly sourced and FSC® certified (FSC Licence Code - C003608), meaning it comes from well-managed forests that adhere to strict environmental and social standards. By choosing FSC® certified Kwila, you can enjoy the benefits of this durable hardwood while supporting sustainable forestry practices.

Yes, Kwila is known to bleed tannins, especially when it's newly installed or gets wet. This can cause staining on nearby surfaces like concrete or tiles. To manage this, it’s recommended to allow the wood to weather before installation or to use a sealant to reduce tannin bleeding. Regular cleaning and maintenance can also help minimise the impact.

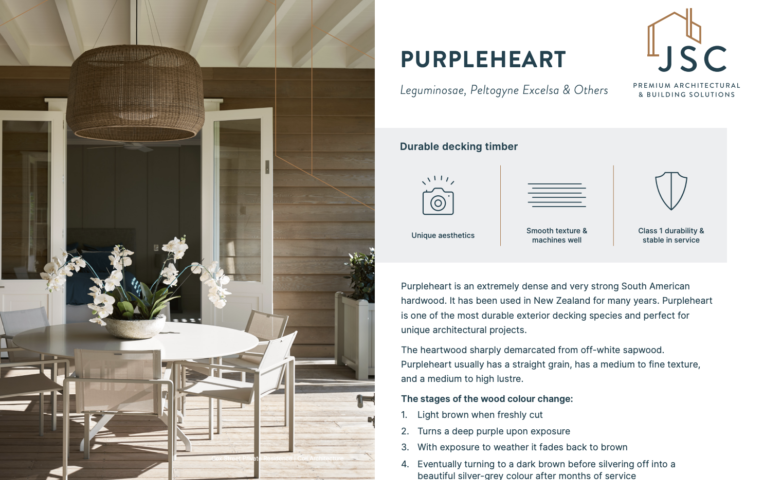

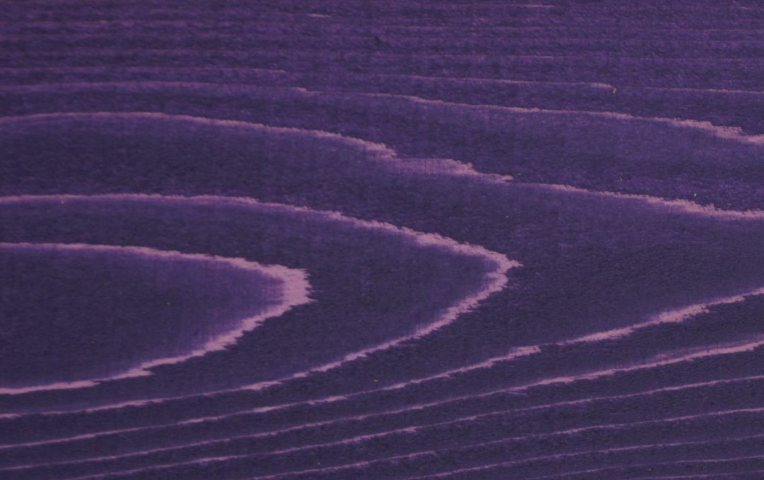

Purpleheart transitions from light brown when freshly cut to a deep purple upon exposure, and eventually matures to a silver-grey as it weathers.

Purpleheart typically starts transitioning from its deep purple hue to a silver-grey within 6 to 12 months of exposure to sunlight and weather conditions. The exact timing can vary based on environmental factors, such as the amount of direct sunlight and exposure to the elements.

Yes, Purpleheart’s durability and aesthetic appeal make it an excellent choice for both residential and commercial projects.

Yes, JSC Purpleheart is FSC® certified, ensuring it is sourced from responsibly managed forests.

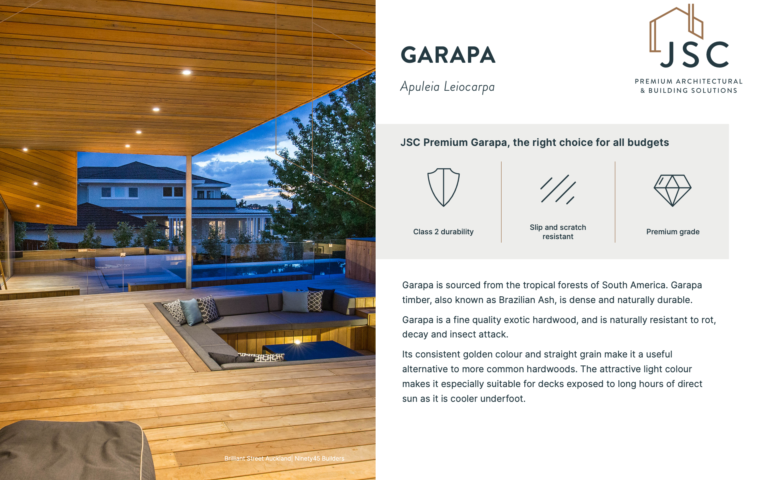

Garapa offers a more cost-effective alternative to other hardwoods while still providing excellent durability and aesthetic appeal.

Yes, JSC’s Premium Garapa is FSC® certified, ensuring that it comes from responsibly managed forests.

Vitex has minimal tannin bleeding, making it less likely to stain concrete and other surfaces compared to other hardwoods like Kwila.

Yes, Vitex’s durability and aesthetic appeal make it ideal for both residential and commercial decking and exterior structures.

Vitex is sustainably sourced from community-based operations in the Solomon Islands. More here

Yes. Both JSC Scumble® and JSC Coda® are suitable for interior and exterior applications. However, for exterior use, the choice of colour is critical, as darker colours can increase heat absorption, potentially leading to timber movement or warping. Factors such as timber species, board profile, and board size should also be considered. It’s recommended to consult a JSC representative to ensure your chosen colour and timber combination are suitable for your project.

JSC Coda® Luxury Interior Wax, also known as 'Lux Wax' is designed exclusively for interior timber surfaces only.

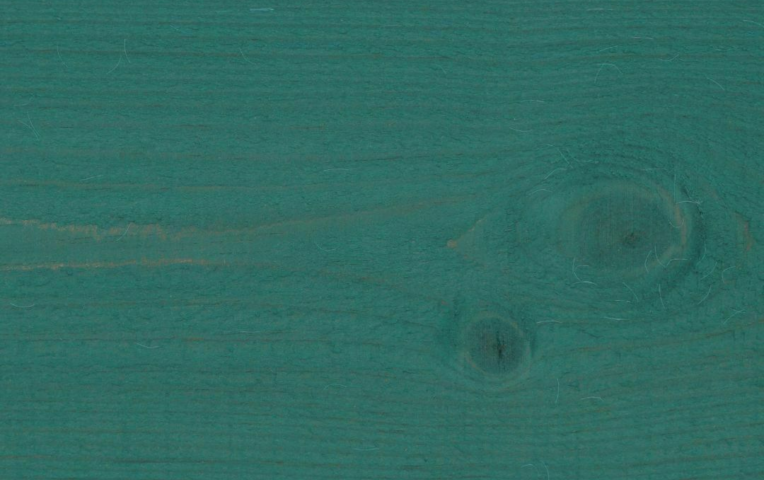

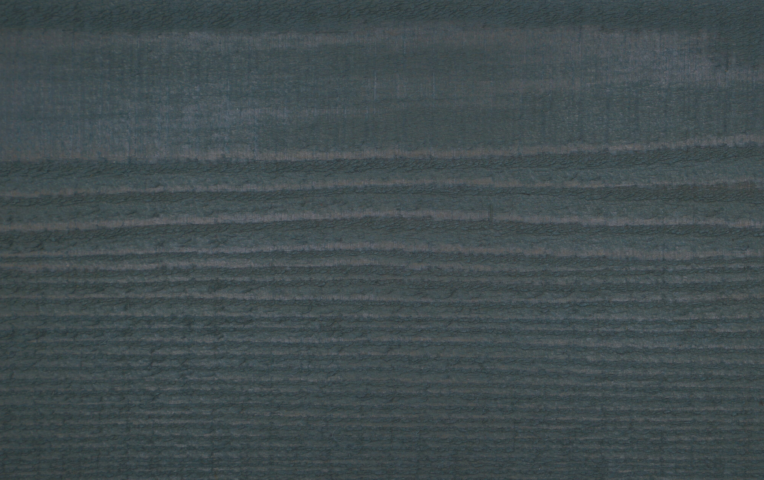

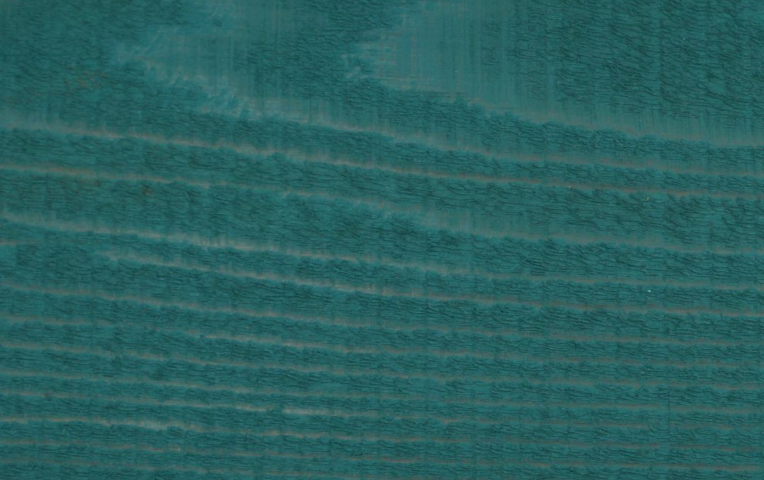

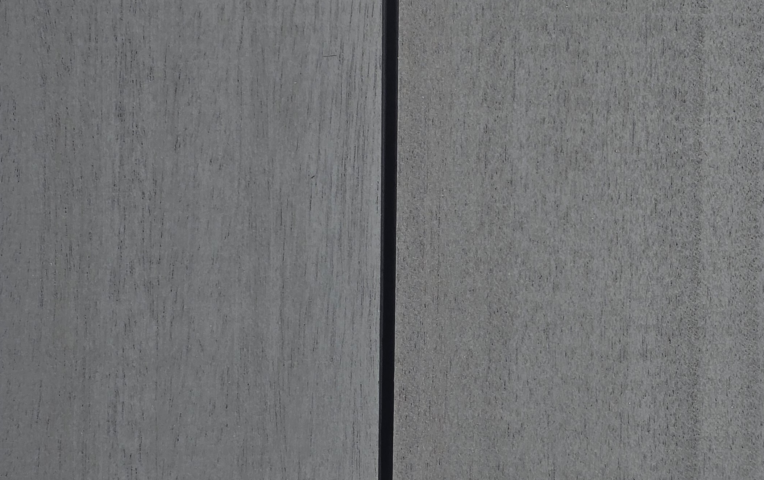

JSC offers a range of coatings to suit different project needs:

- JSC Scumble® is a high-pigment coating that delivers excellent coverage, longer recoating intervals, and enhanced protection. Suitable for interior and exterior applications, it is available in 10+ colours, making it ideal for projects prioritising durability, longevity, with a higher coverage finish. JSC Scumble’s range leans towards natural tones inspired by the New Zealand landscape and creates a more covered look than JSC Coda™, while still retaining the natural timber appeal.

- JSC Cod® offers a semi-transparent finish, showcasing the natural grain and texture of the timber. With 15 colours and a clear option, it features a diverse colour palette, including striking, bold options suited to architectural projects with distinctive aesthetics. Also suitable for interior and exterior use.

- JSC Coda™ Luxury Interior Wax often referred to as “Lux Wax” is crafted exclusively for interior use, providing a silky matte finish that enhances the timber’s natural beauty while offering moisture protection and lasting performance.

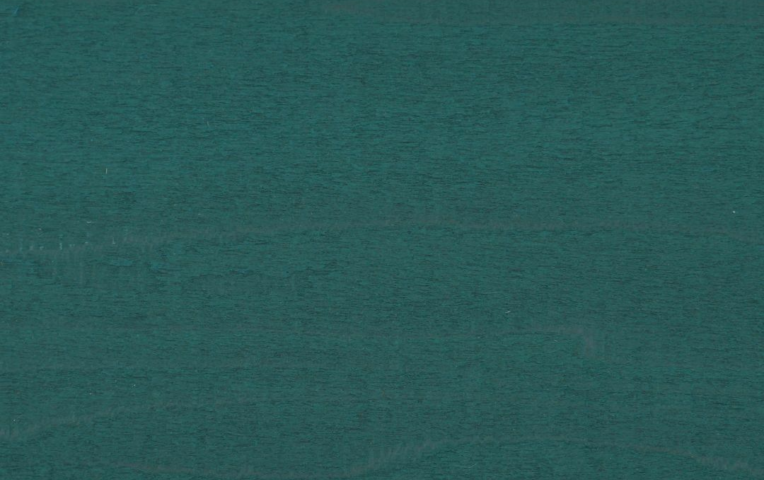

Samples are available to review coatings on your selected species - Visit jsc.co.nz/jsc-samples

- Cleaning: Perform annual cleaning with a soft brush and mild detergent to remove surface contaminants such as dust, pollen, or mould. Avoid high-pressure water blasters, as they can damage the timber and coating.

- Inspections: Conduct inspections every 12 months (or every 6 months in harsher environments like coastal areas) to identify signs of wear or degradation.

- Recoating:

- JSC Scumble®: Typically requires recoating every 3-5 years*

- JSC Coda®: Typically requires recoating every 2-3 years*

*Recoating intervals depend on factors such as site exposure, timber species, coating colour, and maintenance. These intervals may extend beyond these timeframes with regular maintenance and site-specific care.

Maintenance coats should be applied if there are visible signs of wear, such as loss of water repellence, colour fading, or exposed end-grain. Regular maintenance not only preserves the coating but also ensures the timber remains protected and visually appealing. For more information see the full JSC Coatings Guide

For the junction of fascia boards, a recommended approach is:

1. Butt Joints

- Fascia boards should be butt-joined directly over structural supports

- The joints must be centered over supporting members for proper structural integrity

- Each board end must be securely fixed to the supporting structure

2. Weather Protection

- Apply a compatible sealant at the back of the cut boards at the junction point

- For painted fascia boards, use a full-length sealant at the junction

- For stained fascia boards, ensure all cut ends are properly sealed before installation

3. Material Considerations

- For Radiata Pine fascia, avoid mitre joins as they tend to open up over time

- For Cedar or TMT species, mitre joins may be acceptable with proper sealing

- Pre-drill all fixings near the ends of boards to prevent splitting

4. Flashing Protection

- Consider using metal flashing over the top edge of fascia boards to provide additional weather protection

- Ensure proper overlap with roofing elements to maintain weather tightness

Please note that while JSC may offer these suggestions based on our experience with timber, the final design responsibility remains with the architect/designer to ensure compliance with the New Zealand Building Code (NZBC). Contact us if you require additional technical insight.

If you're unable to find the specific detail via the Technical Resources search, please contact Technical Help here and we can forward you the detail in question, or advise a common approach people take to that aspect. Please note, our technical team is unable to provide sign-off on specific details. The responsibility for ensuring the detail is appropriate for the intended application and compliant with the New Zealand Building Code (NZBC) lies with the designer and builder.

Please note that while junction details with brick cladding are not specifically part of our CodeMark certified details, based on our experience with timber cladding, we recommend the following approaches:

- Ensure that timber weatherboards are not in direct contact with the brick cladding. Use appropriate flashing (such as a J-mould) to prevent contact and provide a weathertight junction.

- The cavities for both cladding systems must be fully isolated, preventing any airflow between the two cavities.

- Maintain a minimum 10mm gap between the timber cladding and brick to allow for differential movement between the different materials.

- For vertical cladding meeting brick, use a J-mould flashing to create a clean edge and ensure water is directed away from the junction.

- Apply a compatible sealant between the flashing and the timber cladding. Bostik MS Safe Seal and Bostik Seal N Flex Façade are compatible with JSC Scumble and JSC Coda coating systems.

For more detail, contact JSC Technical Support here. As a friendly reminder, while JSC may offer comments and suggestions on the development of specific details for your consideration, we are unable to comment on compliance if the detail falls outside our CodeMark scope. It is the responsibility of the architect/designer to ensure that the details are appropriate for the intended application and compliant with the New Zealand Building Code (NZBC).

Our cladding systems are covered by our CodeMark Certification, the most current version which is available via our Technical Resources area. Upon reviewing this, if you have any queries, please send a detailed enquiry here or contact your local JSC representative.

TMT is a cost-effective and environmentally friendly choice, offering a comparable durability and distinctive colours. We're happy to help you work through any queries and provide a quote to compare options - contact us today.

Our cladding systems' certification and scope of limitations (including applicable timber species) are documented in our CodeMark certificates, all of which are available under Technical Resources. Upon review of these details, if you have any queries, please contact us.

For an internal corner junction between, say vertical shiplap cladding and horizontal bevel back cladding, a scriber is required.

JSC recommend cleaning your hardwood deck annually using a brush with water and mild detergent, a bleach solution (1:10) or a proprietary deck cleaner. Do not direct high pressure water on any timber deck, as it can permanently damage the timber. When cleaning your deck with a proprietary deck cleaner, always follow the manufacturer's instructions. Typically, the cleaning process involves soaking the deck (avoiding direct sunlight), scrubbing it, focusing on grooves and gaps, and rinsing thoroughly. Ensure the deck is allowed to dry, but never let it dry with cleaning product residue on the surface.

Keep your deck clean to avoid them. These can occur due to inherent timber characteristics or caused by site contamination. Some species, like Purpleheart, Garapa and Vitex may develop spots due to a reaction with alkaline substances or metal particles. Site-related contamination can occur from activities such as cutting fibre cement, brick, metal or concrete nearby, as the particles can react with the timber. Organic contamination can also occur, such as flowers or seeds falling onto the deck. These marks from contamination are more noticeable on light-coloured timber decking. Depending on severity, black marks may be cleaned using deck cleaners. Attend to the clean-ups immediately you see them developing.

These checks are primarily cosmetic and do not affect the structural integrity or soundness of your deck. Fine lines in the timber are a natural occurrence as the timber adjusts to environmental conditions, such as moisture changes and UV light.

Decking should be kept dry and protected from the weather until installation. Decking boards must be stored off the ground on dry, clean bearers and covered to prevent exposure to sun, rain, and airborne contaminants. Direct sunlight can cause uneven fading and colour variations, while wet, block-stacked decking may stain, discolour, or develop mould. Proper storage is essential to achieve a well finished installation. Decking should remain in its original packaging until just before installation. Do not open the packaging and leave the boards exposed for an extended period before or during installation. Protect packed decking from weather, as wet timber will shrink after installation. Moisture content should be consistent across all decking boards before installation. If the packs are not stored properly, boards in the middle of a pack can have a different moisture level than those on the outside, leading to potential movement after installation. If the moisture content is inconsistent, some boards will shrink while others will expand, creating uneven gaps and affecting the overall deck

JSC Clipp® is a concealed-fix batten system designed for decorative interior applications. It enables clean, uninterrupted timber lines without visible fixings on the face of the timber, delivering a refined aesthetic with easier installation.

It’s ideal for internal feature walls and ceilings in residential, commercial, hospitality, and multi-unit environments. It’s not intended for external use or high-impact zones.

Unlike conventional battens that rely on visible face-fixing with screws or nails, JSC Clipp® uses a concealed clip-in batten system. While some timber panelling systems also allow for hidden fixing, JSC Clipp® is purpose-designed for batten features, enabling easy removal and replacement of individual battens without disrupting the overall installation. This makes it ideal for applications where clean aesthetics and future accessibility are important.

- No visible face fixings - Clean, uninterrupted timber face

- Faster and simpler installation

- Reversible and removable battens

- Compatible with a wide range of JSC timber species and finishes

JSC Clipp® is compatible with several JSC softwoods and thermally modified timbers. Profiles and species are customisable depending on design intent. Contact us to discuss available options.

In most cases, JSC Clipp® is best suited to flat surfaces. For curves or non-standard applications, speak to a JSC representative to explore alternative solutions from our timber panelling or batten range.

Timber battens that are clipped to an aluminium Rail. No face fixing is required. Installers should refer to the JSC Clipp® Installation Guide for full instructions.

Minimal maintenance is required. Interior timber should be periodically dusted or wiped down with a dry or damp cloth. Avoid abrasive cleaners. View the JSC Clipp Installation & Specification guide for more detail.

JSC offers clear and colour-coated finishes compatible with the timber battens in the system. Visit our Coatings Page to explore available tones and discuss custom options with our team.

The JSC Clipp® System is available in two spacing options:

- Pre-configured rails with 60mm or 80mm centres:

– These enable fast installation

– Battens can be removed and reinstalled using the designated Clipp® removal tool - Adjustable spacing version (customisable on site)

– Offers design flexibility

– Clips are manually fixed with screws, so battens cannot be removed using the tool

– Removal may require disassembling fixings, making it less serviceable than the pre-configured rail

We recommend choosing the configuration that aligns best with your project’s design intent and long-term serviceability requirements.

Yes. JSC Clipp® can be installed in vertical, horizontal, or ceiling applications, depending on the aesthetic intent and design requirements.

JSC Clipp is a decorative system and is not typically subject to fire performance compliance. Where required, intumescent coatings can be specified to assist with compliance. For advice, please get in touch.

Yes, JSC Clipp® battens may be coated with approved intumescent finishes where project-specific fire requirements exist. Ensure the coating is tested on the intended timber species and finish, and applied per manufacturer specifications.

Yes. JSC weatherboards can be installed direct fixed in accordance with E2/AS1. See our PASS certificate for compliance details: Direct Fixed PASS Certificate.

We supply through trusted merchants, but we work directly with architects, builders, and homeowners to provide timber solutions, samples, and technical guidance.

We supply premium timber cladding, hardwood decking, screens & battens, hardwoods, thermally modified timber, interior panelling, and timber coatings, with both standard and custom profiles - available across Auckland and surrounding regions.

We supply premium timber cladding, hardwood decking, screens & battens, hardwoods, thermally modified timber, interior panelling, and timber coatings, with both standard and custom profiles - available across Christchurch and surrounding South Island regions.

We supply premium timber cladding, hardwood decking, screens & battens, hardwoods, thermally modified timber, interior panelling, and timber coatings, with both standard and custom profiles - available across Hamilton, Waikato, Bay of Plenty, Coromandel, and surrounding regions.

We supply premium timber cladding, hardwood decking, screens & battens, hardwoods, thermally modified timber, interior panelling, and timber coatings, with both standard and custom profiles - available across Wellington and Lower North Island surrounding regions.

Yes. Every piece of our timber is responsibly sourced from suppliers with verifiable environmental standards, legality, and Chain-of-Custody certification. We are a founding member of NZITTG and follow the 2018 Charter of Understanding, and we regularly review suppliers for best-practice forest management

Yes. All our timber is responsibly sourced, with many species carrying FSC® or PEFC certification, and our Thermally Modified Timber (TMT) range uses a chemical-free heat process for enhanced stability and durability. You can learn more about our commitment to responsible sourcing here - https://jsc.co.nz/sustainability

Yes. Many of our timbers perform well in coastal and high-exposure environments. The best choice depends on your project requirements and site conditions, so we recommend speaking with our team to ensure the timber solution is fit for purpose.

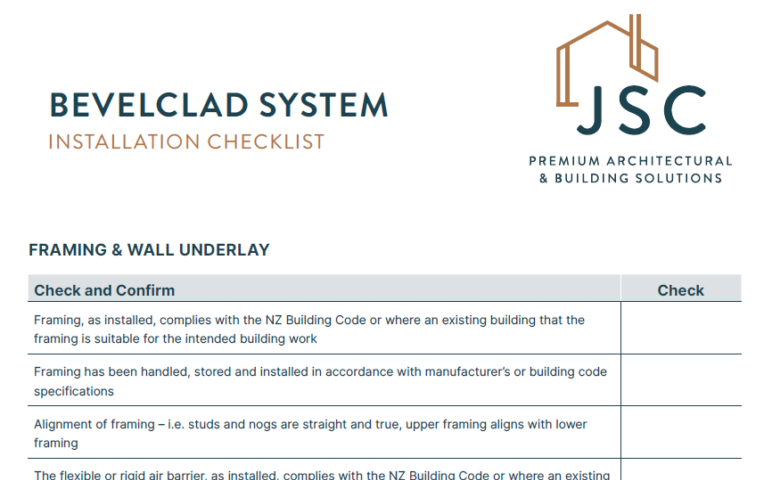

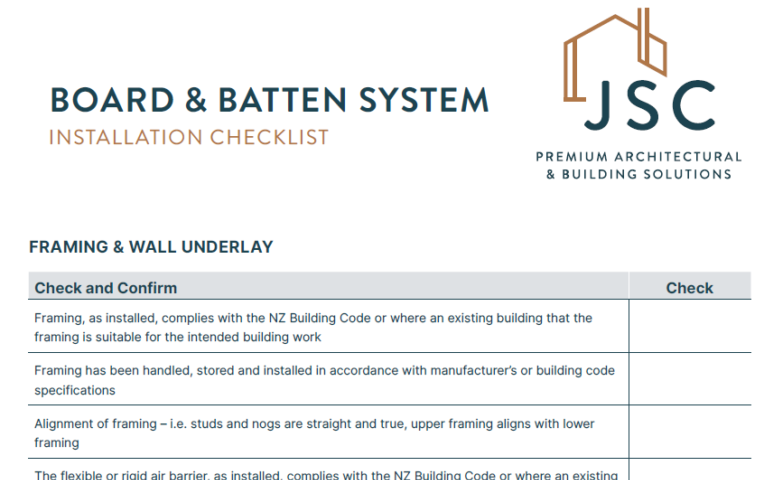

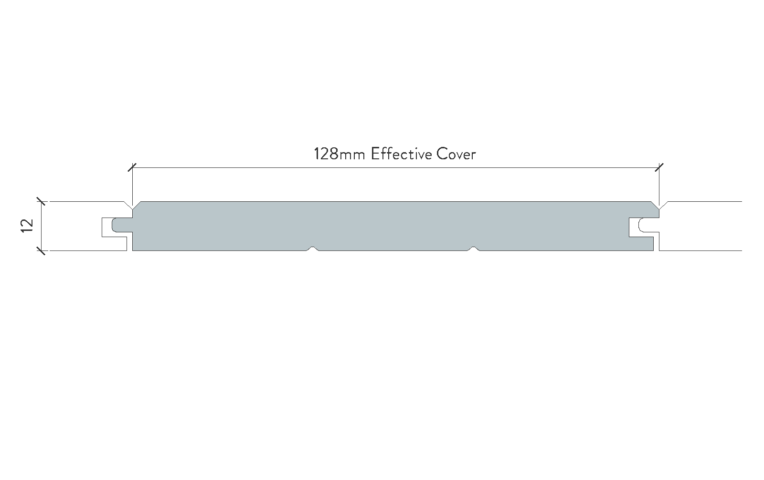

Yes. JSC offers CodeMark-certified timber cladding systems - including VertiClad, RustiClad, BevelClad, and Board & Batten - each with complete installation specifications and technical details. Our CodeMark certification provides formal evidence of compliance with the New Zealand Building Code, including E2 requirements for weathertightness. All technical documentation, drawings, and system guides are available from our Technical Downloads section to assist architects, designers, and builders in meeting consent and compliance requirements.

Contact JSC directly or request through our website. We can send samples or our Inspiration Box for your studio/office - https://jsc.co.nz/jsc-samples

Yes, we supply timber solutions throughout the country including Auckland and surrounds and can arrange delivery via our merchant partners.

Yes, we supply timber solutions throughout the country including Waikato, Bay of Plenty, Coromandel and surrounds and can arrange delivery via our merchant partners.

Yes, we supply timber solutions throughout the country including Christchurch and surrounds and can arrange delivery via our merchant partners.

All of JSC's hardwood species are rated Class 1 or Class 2 for durability under the EN 350 standard. Actual performance depends on factors such as species selection, installation method, site conditions, and ongoing maintenance. Correct care can help maximise the service life of your decking.

Maintenance depends on the application. For cladding, maintenance is required for all timber cladding – follow the JSC Timber Cladding Maintenance Guide for details on inspection, cleaning, recoating methods, and interval recommendations. Thermally Modified Timber is dimensionally stable, which helps reduce movement-related issues, but coating is still recommended for protection in the NZ climate. We recommend coating it with a high-quality oil or stain and choosing long-lasting products such as JSC Scumble®, which typically extends recoating intervals to approximately. https://jsc.co.nz/technical/exterior-timber-weatherboard-cladding-maintenance-guide

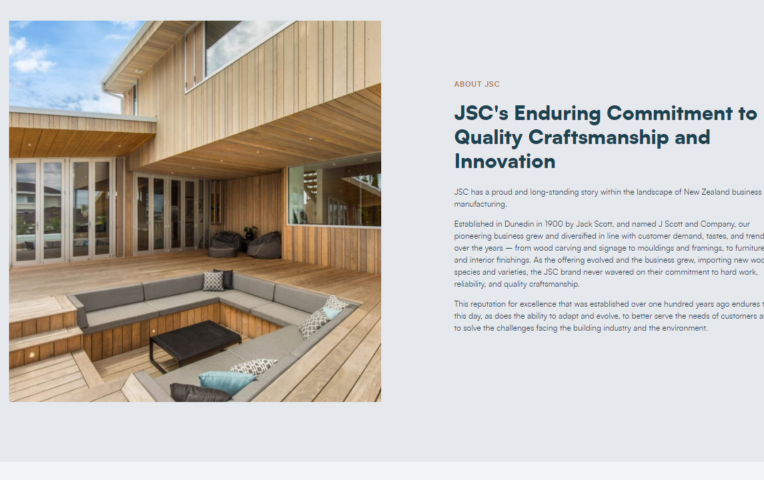

We source timber from responsibly managed forests in New Zealand and internationally, with many species carrying FSC® or PEFC certification. Our hardwoods and softwoods are legally verified and selected for durability, performance, and sustainability - whether for residential, commercial, or marine applications. We work closely with trusted suppliers in New Zealand, Fiji, South America, Indonesia, West Africa, and Australia to ensure secure supply, ethical forestry, and project-specific solutions. JSC is an active member of NZITTG and NZTIA, reflecting our leadership in sustainable timber sourcing and industry best practice.

JSC does not advise on fire resistance ratings or safety classifications. Compliance with NZBC clauses C1–C6 (fire safety) must be confirmed by the project’s designer or a suitably qualified professional. Any statements on fire performance, including intumescent coatings, should be obtained directly from the coating manufacturer.

Coastal environments require careful species and coating selection. JSC offers timbers such as JSC TMT® and select timber species that perform well in salt-laden air when paired with appropriate coatings and best-practice detailing. Exposure category (sea spray vs. sheltered coastal) influences coating intervals and profile suitability - our team can assist in recommending the right solution for your site.

In NZ conditions, fibre cement and metal cladding often require less frequent maintenance but lack the natural warmth and sustainability of timber. Timber offers a renewable, low-embodied-carbon option with repairable surfaces and long service life when maintained. Choosing stable species like JSC TMT® (Thermally Modified Timber) and coatings with extended recoat intervals can reduce lifecycle costs. See Maintenance Guide.

JSC’s timber cladding systems, including RustiClad, VertiClad, BevelClad, and Board & Batten, hold CodeMark certification, giving assurance of compliance in all New Zealand wind and seismic zones when installed as per our specifications. JSC CodeMark-certified cladding systems have a minimum durability of 15 years when installed and maintained in accordance with our specifications. Actual lifespan will depend on the timber species selected, site conditions, coating systems, and maintenance. Species with high dimensional stability, such as thermally modified timber, Western Red Cedar, and Alaskan Yellow Cedar are recommended for projects in exposed environments. Correct installation, coatings, and regular maintenance help ensure ongoing performance. For specific detailing and compliance information, refer to our Technical Documents & Installation Guides or speak with our team for project-specific recommendations.

JSC’s Technical Team and Architectural Business Development team works directly with architects, designers, and builders to provide tailored specification advice, compliance guidance, and detailing support for even the most complex projects. From early design stages through to installation, we can assist with species selection, coating guidance, system detailing, and meeting compliance requirements. Samples and CAD details are available to assist with design coordination and specification. Get in touch via our team via the contact us page or speak with your local JSC representative to speak about your project-specific requirements.

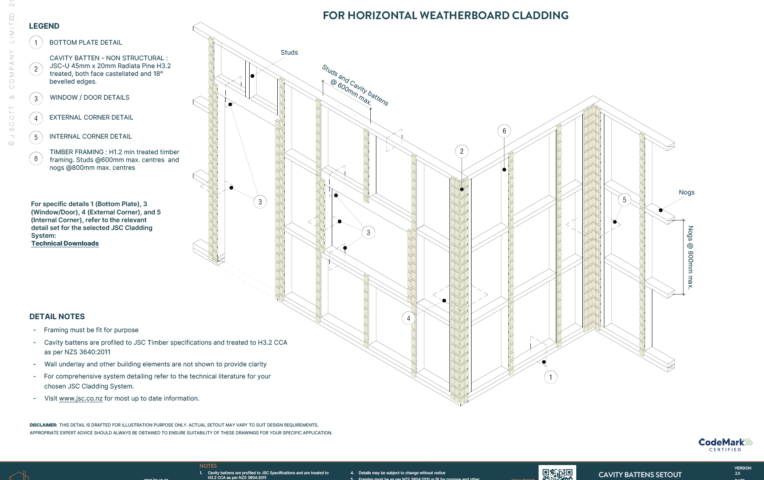

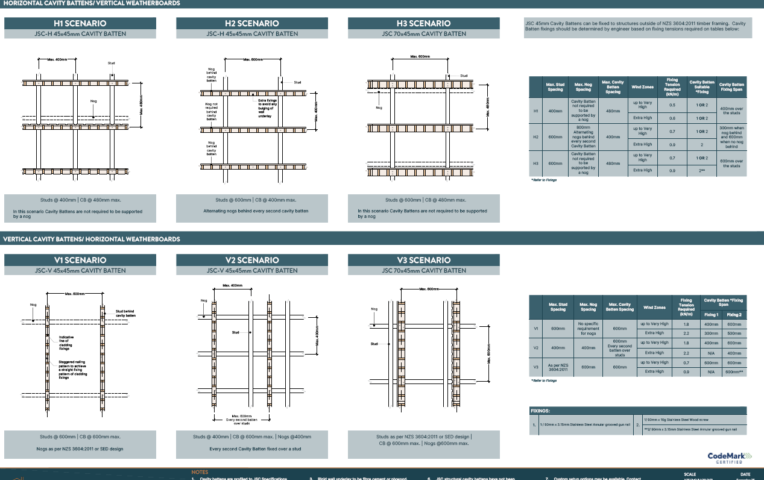

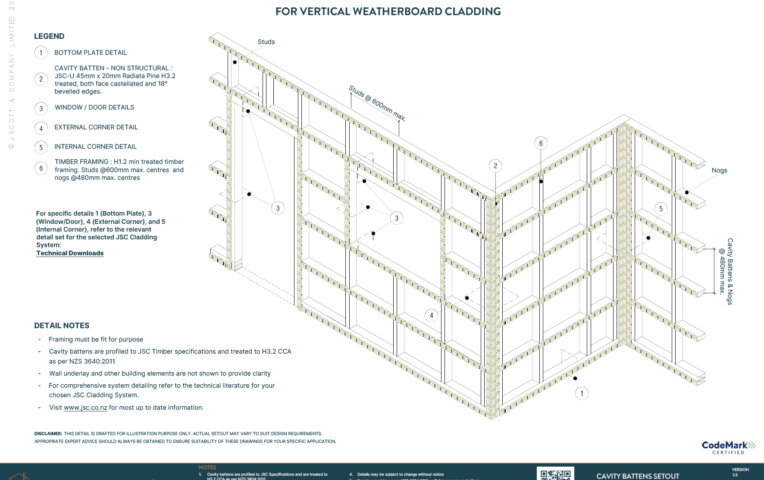

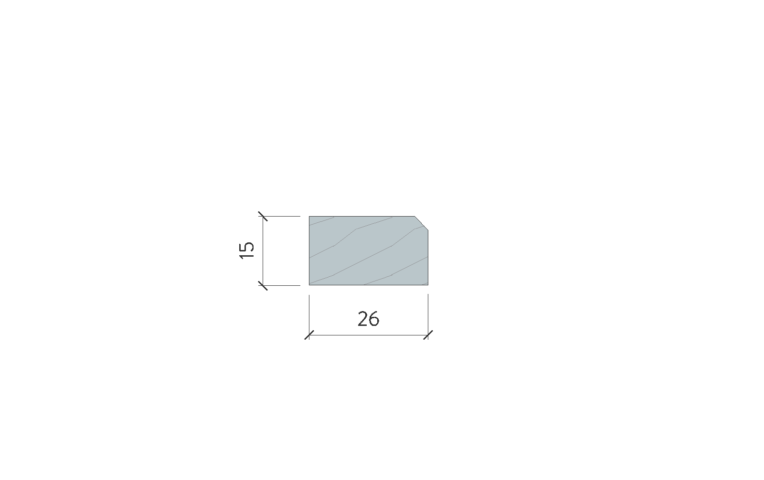

JSC timber cladding systems are designed for installation over either 20 mm non-structural or 45 mm structural castellated H3.2-treated cavity battens, as per our CodeMark-certified systems. Installation requirements, including cavity batten layout, flashing and fixing specifications are provided in the relevant JSC Installation and Specification Guides and Technical Drawings for each cladding system.

Please refer to the appropriate system documentation, available at https://jsc.co.nz/downloads, and follow these details in full to maintain compliance and warranty coverage.